FlexFeeders

Custom Flex Feeders from Bellco Feeders

Bellco Feeders' flexible feeding solutions supply parts to an industrial vision-guided robot. With its backlit tray and three-axis vibration technology, our flex feeder provides an enhanced user experience. This technology efficiently moves components in various directions across the surface, ensuring their random scattering.

When the vision system notifies the flex feeder that there are not enough pickable parts on the surface, the hopper and flex feeder will turn on, gently shaking the components again to reorganize them.

We can configure bulk part hoppers that provide a continuous flow of material to the vibrating tray and minimize operator interaction.

- Quiet and gentle operation

- Programmable vibration sequences with 3-axis vibrating technology to move parts in all directions

- Highly adaptable and easily customized - possible to supply a complete range of parts

- Suitable for parts that have unique geometries

- Ideal for restoration projects

- With a compact design that optimizes the operator’s time and floor space

- Optional backlit pick area to pair with vision guided robotic applications

It is important to remember that flexible part feeders are not suitable for every automation system. Bellco Feeders will work with you to identify and implement the right part feeding system for your specific requirements.

Bellco Flex Feeders Standard Sizes

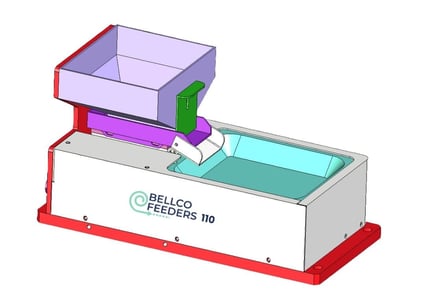

Bellco 110

-

Pick Area: 130 x 104 mm (~5 x 4 inches)

-

Overall Dimensions: 370 x 169 mm (~14.5 x 6.6 inches)

-

Maximum Load: 0.8 kg (~1.7 lbs.)

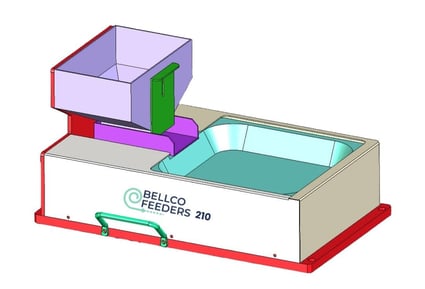

Bellco 210

-

Pick Area: 196 x 208 mm (~7.7 x 8 inches)

-

Overall Dimensions: 470 x 270 mm (~18.15 x 10.6 inches)

-

Maximum Load: 1.4 kg (~3 lbs.)

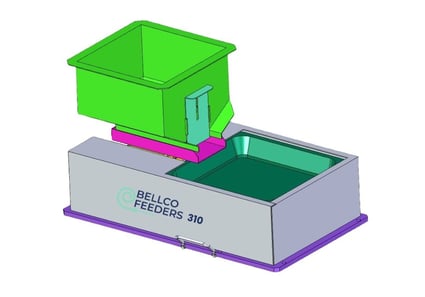

Bellco 310

-

Pick Area: 280 x 330 mm (~11 x 12.9 inches)

-

Overall Dimensions: 700 x 400 mm (~27 x 16 inches)

-

Maximum Load: 2.0 kg (~4.4 lbs.)

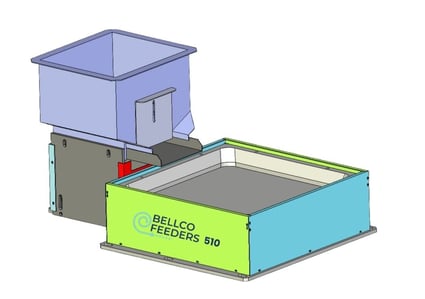

Bellco 510

-

Pick Area: 440 x 440 mm (~17.3 x 17.3 inches)

-

Overall Dimensions: 750 x 580 mm (~29.5 x 22.8 inches)

-

Maximum Load: 3.0 kg (~6.6 lbs.)

Features and Benefits

Designed for Simple Robotic Integration

Our flex feeders integrate easily with your vision-guided, pick-and-place robot applications. The parts can then be placed into the automation equipment directly. You can use our solutions with multiple types of robots, including a vision guided 6-axis or SCARA robot.

Frequently Asked Questions

Ready to Get Started?

We understand the importance of quality components, competitive pricing and on-time deliveries. Our team is available to answer your questions and provide a quote for your custom parts feeding solutions.