The Best Ways to Feed Parts from Bulk into an Automated Machine

The best way to feed parts from bulk into an automated machine depends on several factors, including the type and characteristics of the parts, the production volume, the level of automation, and the specific requirements of the automated machine. Here are some common methods for feeding parts into automated machines:

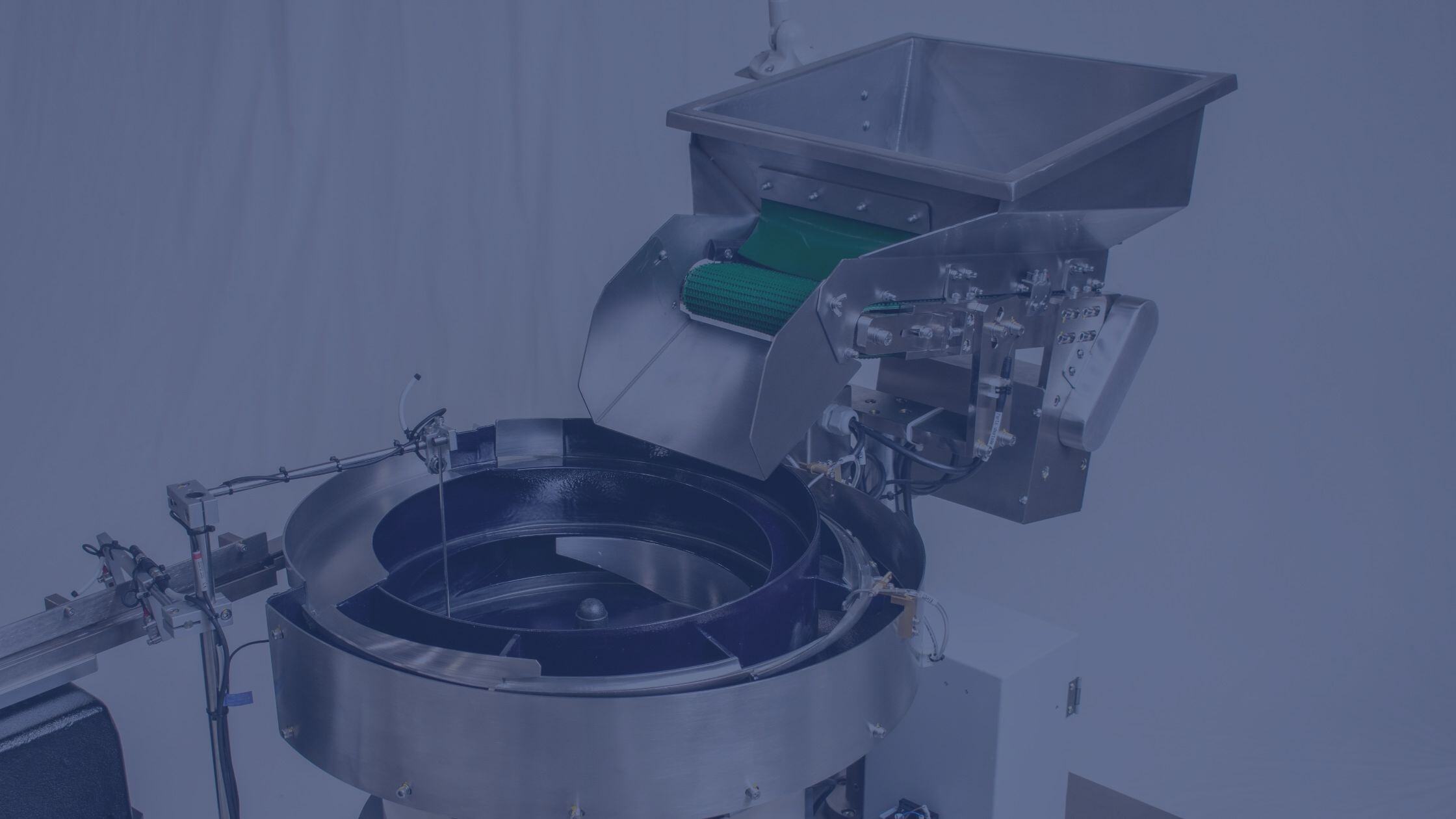

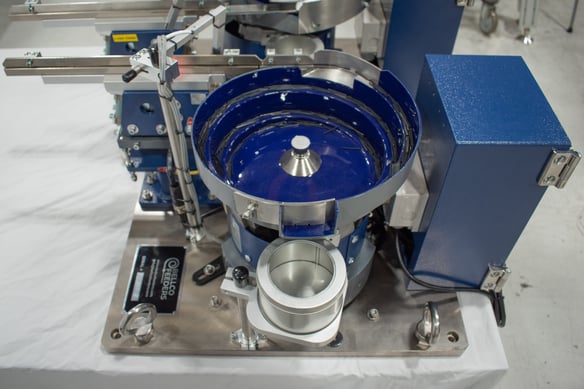

Vibratory Bowl Feeders:

Vibratory bowl feeders are one of the most popular and versatile methods for feeding small to medium sized parts. They use vibrations to orient and feed parts from a bulk supply. The parts move along a spiral track and are singulated and oriented before being presented to the automated machine. The best application for a vibratory bowl feeder can vary depending on the specific requirements of a manufacturing or assembly process. Here are some of the most common and well-suited applications for vibratory bowl feeders:

- Automated Assembly: Vibratory bowl feeders are often used in automated assembly systems to deliver components, such as screws, nuts, bolts, washers, and connectors, to the assembly line. They ensure a steady supply of parts in the correct orientation for assembly robots or operators.

- Packaging and Sorting: Vibratory bowl feeders are used in packaging and sorting operations to align and feed items like caps, lids, small containers, and consumer products for packaging lines. They help maintain a consistent product flow and orientation.

- Pharmaceutical and Medical Devices: In the pharmaceutical and medical device industries, vibratory bowl feeders are used for feeding and orienting small components like pills, capsules, vials, and medical instruments for packaging or assembly.

- Electronics Manufacturing: Vibratory bowl feeders play a critical role in the electronics industry for feeding electronic components, including resistors, capacitors, diodes, and connectors. They ensure precise placement and orientation of components on circuit boards.

- Food and Beverage: In food processing and packaging, vibratory bowl feeders are utilized to handle products such as candies, nuts, screws, and small food items. They maintain hygiene standards and help in consistent product presentation.

- Automotive Manufacturing: Vibratory bowl feeders are used in automotive assembly lines to supply various small parts, such as screws, clips, fasteners, and connectors, to the production process.

- Aerospace: Aerospace manufacturing often involves the use of vibratory bowl feeders for the handling and orientation of components like rivets, bolts, washers, and other fasteners.

- Consumer Goods: Vibratory bowl feeders are employed in the production of consumer goods, such as toys, personal care products, and small appliances, for feeding and orienting parts or components.

- Hardware and Fasteners: In hardware manufacturing, vibratory bowl feeders are ideal for sorting and supplying screws, nuts, bolts, washers, and other fasteners in bulk.

- Bearing and Bushing Assembly: Vibratory bowl feeders are commonly used in bearing and bushing manufacturing for aligning and feeding ball bearings, roller bearings, and bushings for assembly operations.

- Customized Parts Feeding: Vibratory bowl feeders can be customized to handle specific parts or components in unique manufacturing processes where other feeding methods may not be as efficient.

Escapements are mechanical devices that release one part at a time from a bulk supply to regulate the controlled release of individual parts or components. The primary purpose of a part escapement is to ensure that parts are presented in a controlled and sequential manner to downstream processes or assembly stations. This device helps prevent jams, collisions, and misalignment of parts, thus contributing to the efficient and precise operation of the assembly line. They are commonly used in combination with other feeding methods, like at the end of a linear track as parts exit a vibratory bowl feeder.

Hopper and Conveyor System:

Hopper systems can hold a bulk supply of parts, and conveyor belts or vibratory conveyors can transport the parts to the automated machine. Sensors and control systems can be used to regulate the flow of parts and ensure a consistent feed rate.

- A large ground hopper with an elevated conveyor is commonly used in situations where an operator needs to load bulk parts at an ergonomically efficient height and then those parts need to be carried upwards into an automated machine. They are often used in various industrial and material handling applications to store, dispense, or feed materials, such as granular solids, powders, or bulk items, into downstream processes, machines, or conveyors.

Pick-and-Place Robots:

Robotic arms equipped with specialized end-effectors can pick parts from a bulk supply and precisely place them into the machine. Vision systems can be used for part recognition and alignment.

- Pick-and-place robots are commonly used in conjunction with Flex Feeders. A flex feeder is a type of automated part feeding system used in manufacturing and assembly processes. The primary purpose of a flex feeder is to feed a variety of parts or components into an automated assembly or manufacturing system without requiring extensive retooling or changeover when switching between different parts. This flexibility makes them suitable for applications with high product variability or frequent product changes. They are also particularly useful for feeding parts that have unique geometries or may get tangled or caught on each other in other traditional feeding systems.

Conveyors:

Conveyors play a crucial role in manufacturing, facilitating the movement of materials, components, and finished products throughout the production process. They help enhance efficiency, reduce manual labor, and ensure a smooth, continuous flow of materials. Conveyors are used in a wide range of applications within manufacturing, including:

-

- Material Handling: Conveyors are employed to transport raw materials, components, and work-in-progress items between different stages of production. This includes moving items from storage areas to production lines and between various workstations.

- Assembly Lines: Conveyors are integral to assembly lines in automotive, electronics, and other manufacturing industries. They carry components to assembly stations, ensuring the precise and sequential delivery of parts for product assembly.

- Packaging: Conveyors are used in packaging processes to transport items to packaging machinery such as fillers, cappers, labelers, and sealers. They can also transport finished products to packaging and palletizing areas.

- Material Storage: Conveyors help store materials in an organized manner, such as in bulk storage bins or in automated storage and retrieval systems (AS/RS). This allows for easy access and retrieval of materials as needed.

- Quality Control and Inspection: Conveyors enable the efficient movement of products past inspection stations, where they can be checked for defects, dimensions, or other quality parameters.

- Sorting and Distribution: Conveyor systems are used for sorting products based on various criteria, such as size, weight, or destination. They can be equipped with diverters or sortation mechanisms to guide items to the appropriate destination.

- Material Processing: In manufacturing processes like machining, painting, and heat treatment, conveyors transport components or workpieces through different stages of processing, ensuring consistent and controlled movement.

- Pharmaceutical Manufacturing: Conveyors are critical for the production of pharmaceuticals, where precision and hygiene are paramount. They are used to transport ingredients, tablets, capsules, and vials through various production stages.

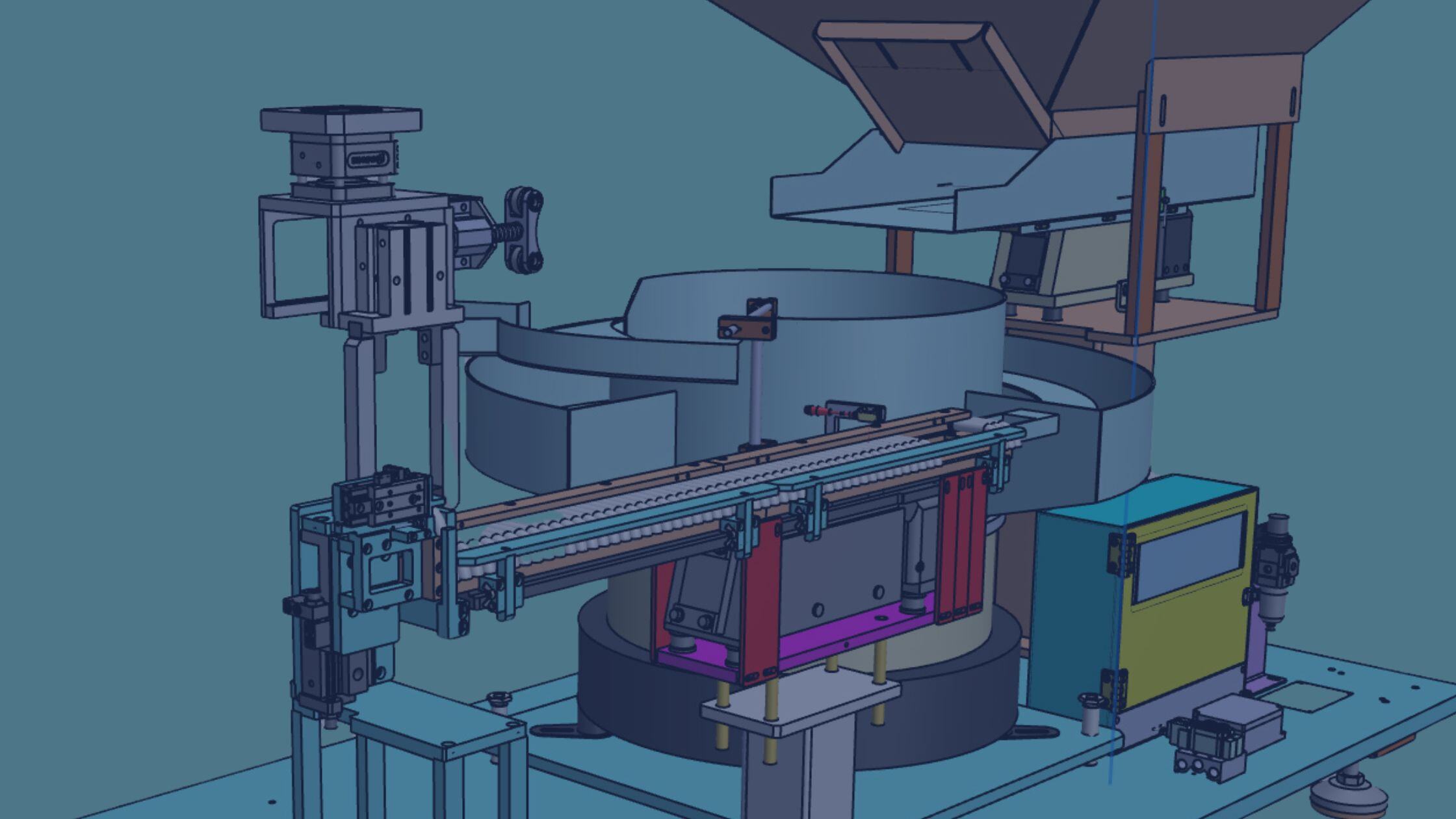

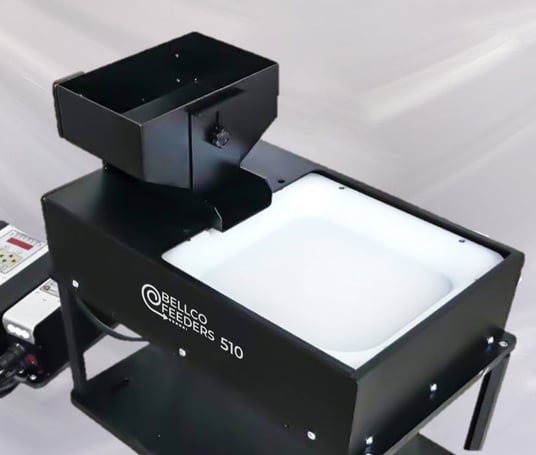

Step Feeders:

An industrial step feeder, also known as a step feeder or step feeder conveyor, is a specialized type of material handling equipment commonly used in industrial automation and manufacturing processes. It is designed to transport and orient parts or components in a controlled and precise manner, ensuring that they are presented to downstream machinery or assembly stations one at a time, typically in a specific orientation. The "step" in its name refers to the distinct, stair-like elevation design that facilitates the orderly progression of parts. Key features and functions of industrial step feeders include:

- Part Orientation: Step feeders are designed to orient parts or components as they move along the conveyor, ensuring that they are in the correct position for the next operation, such as assembly, inspection, or packaging.

- Sequential Feeding: These feeders release one part at a time, allowing for a steady and controlled flow of parts to the next stage of the manufacturing or assembly process.

- Adjustable Design: Many industrial step feeders are adjustable to accommodate various part sizes, shapes, and weights. The steps can be customized to suit the specific requirements of the parts being handled.

- Precision and Accuracy: Step feeders are designed to operate with precision and accuracy, minimizing the risk of jams, collisions, or misaligned parts during the feeding process.

- Automation Integration: Step feeders are commonly integrated into automated manufacturing or assembly lines, working in conjunction with robots, conveyor systems, and other equipment to streamline production.

- Versatility: They can handle a wide range of parts, making them suitable for applications across different industries, such as automotive, electronics, consumer goods, and medical devices.

- Industrial step feeders are frequently used in situations where precise part orientation and sequential feeding are critical, ensuring that parts are presented to downstream machinery or assembly stations in the correct position and at the right time. They help improve efficiency and consistency in manufacturing and assembly processes, reducing the need for manual handling and increasing productivity.

The choice of the best feeding method depends on the specific requirements of the parts, the machine, and the production process. Factors such as part size, shape, weight, fragility, orientation, and production speed all play a role in determining the most suitable method. It's often necessary to work with automation experts or engineers to design and implement an effective feeding system that integrates seamlessly with the automated machine.

Bellco Feeders, is a company specializing in the design and manufacturing of high-quality vibratory bowl, step, and flex feeders, which are used in various industries for the automated feeding and orientation of parts and components. They are based in Cleveland, Ohio, USA and serve customers throughout the continental US.

Bellco Feeders provides custom automation solutions, including the design and fabrication of custom parts feeding systems. These feeders are commonly used in industries such as automotive, electronics, medical devices, consumer goods, and more. Their equipment helps facilitate the efficient and precise handling of parts in manufacturing and assembly processes and they are known for providing innovative solutions to meet the specific automation needs of their customers. Bellco has a strong reputation for providing automation solutions that improve production efficiency, reduce labor costs, and enhance product quality. Their solutions are used in a variety of industries and applications to meet the demands of modern manufacturing and assembly processes.