VibratoryBowl Feeders

Modern innovation. Timeless quality. Only at Bellco Feeders.

Our Standard Package Includes:

Industry Case Studies

Medical & Life Sciences

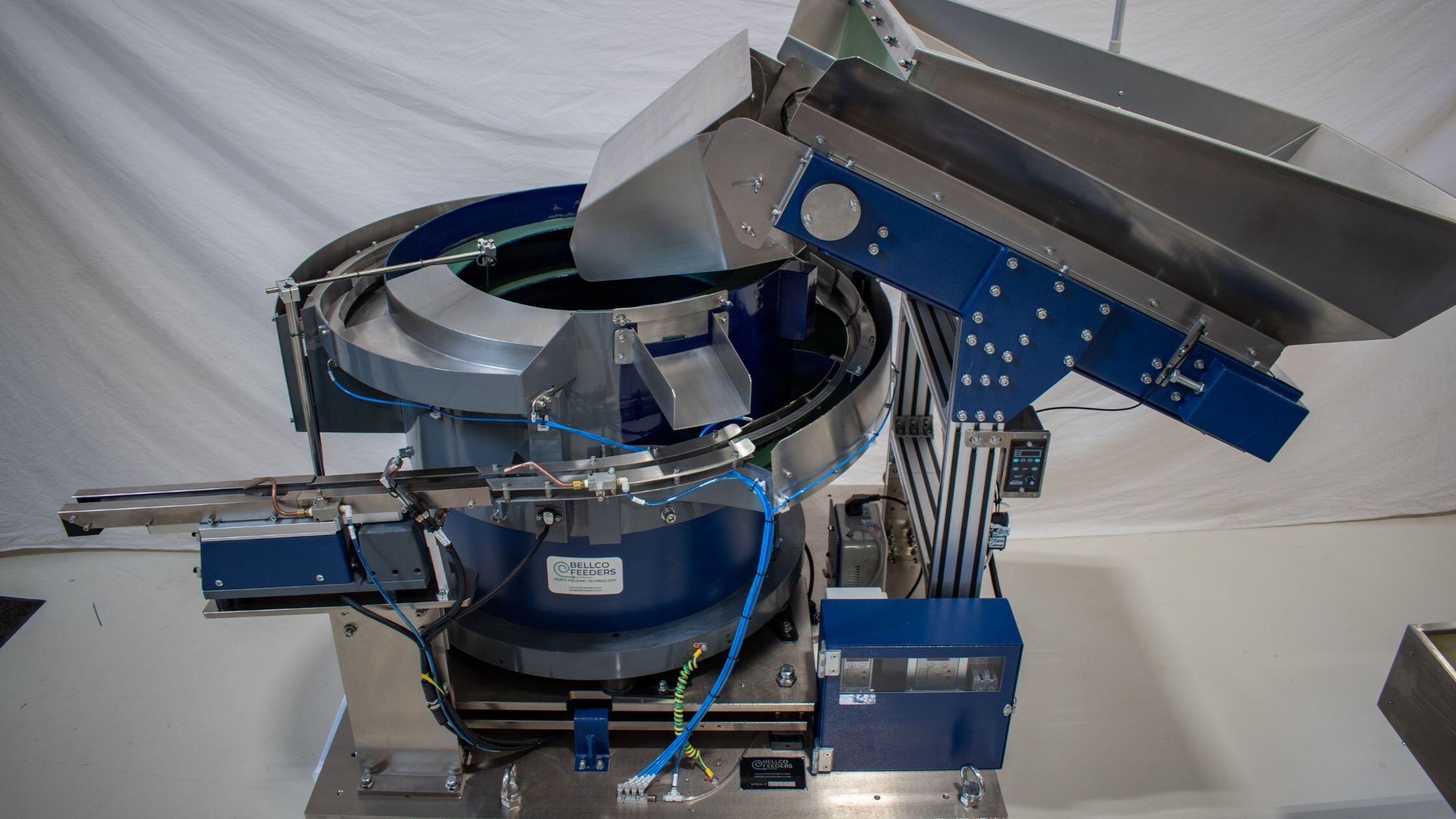

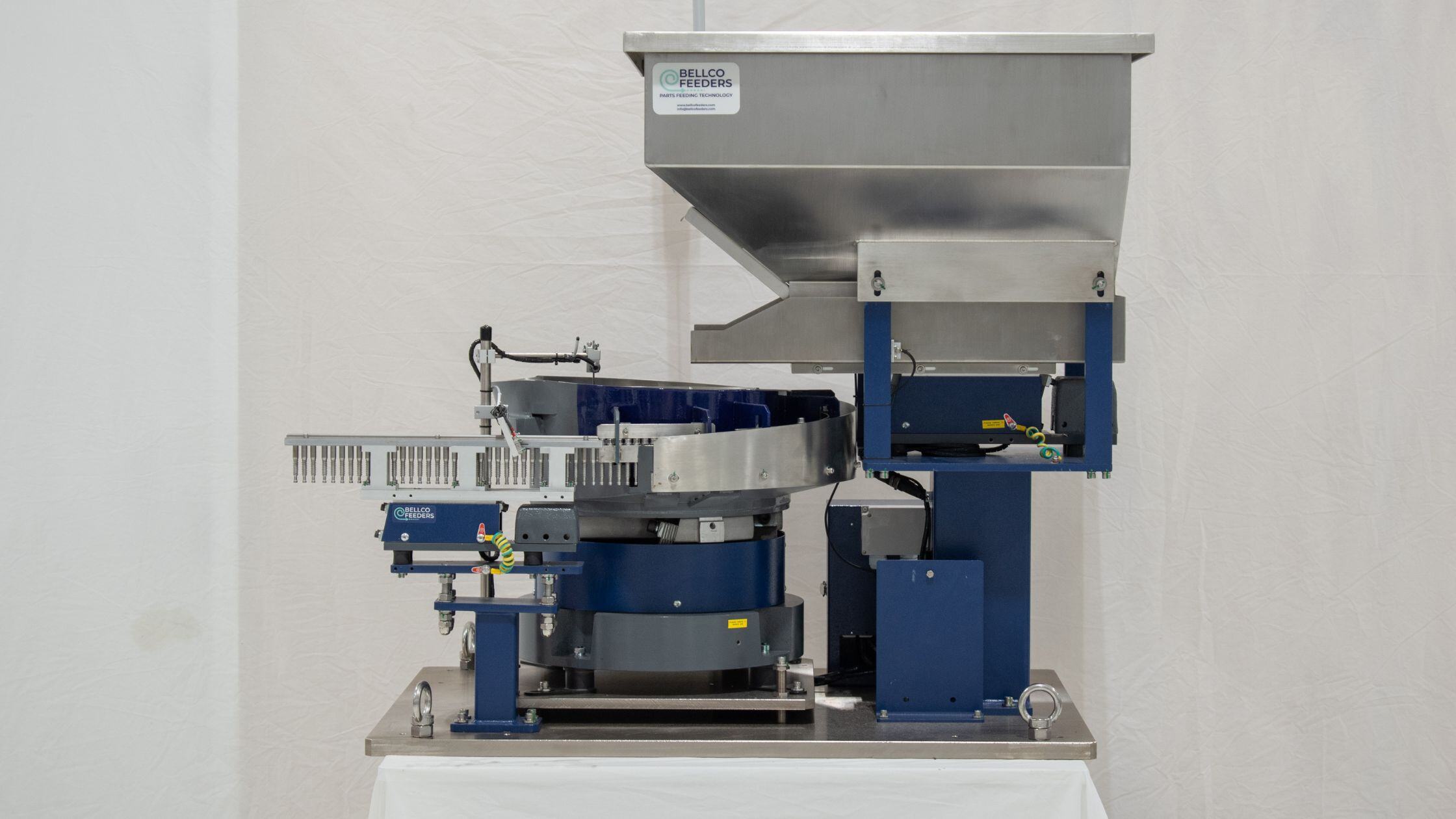

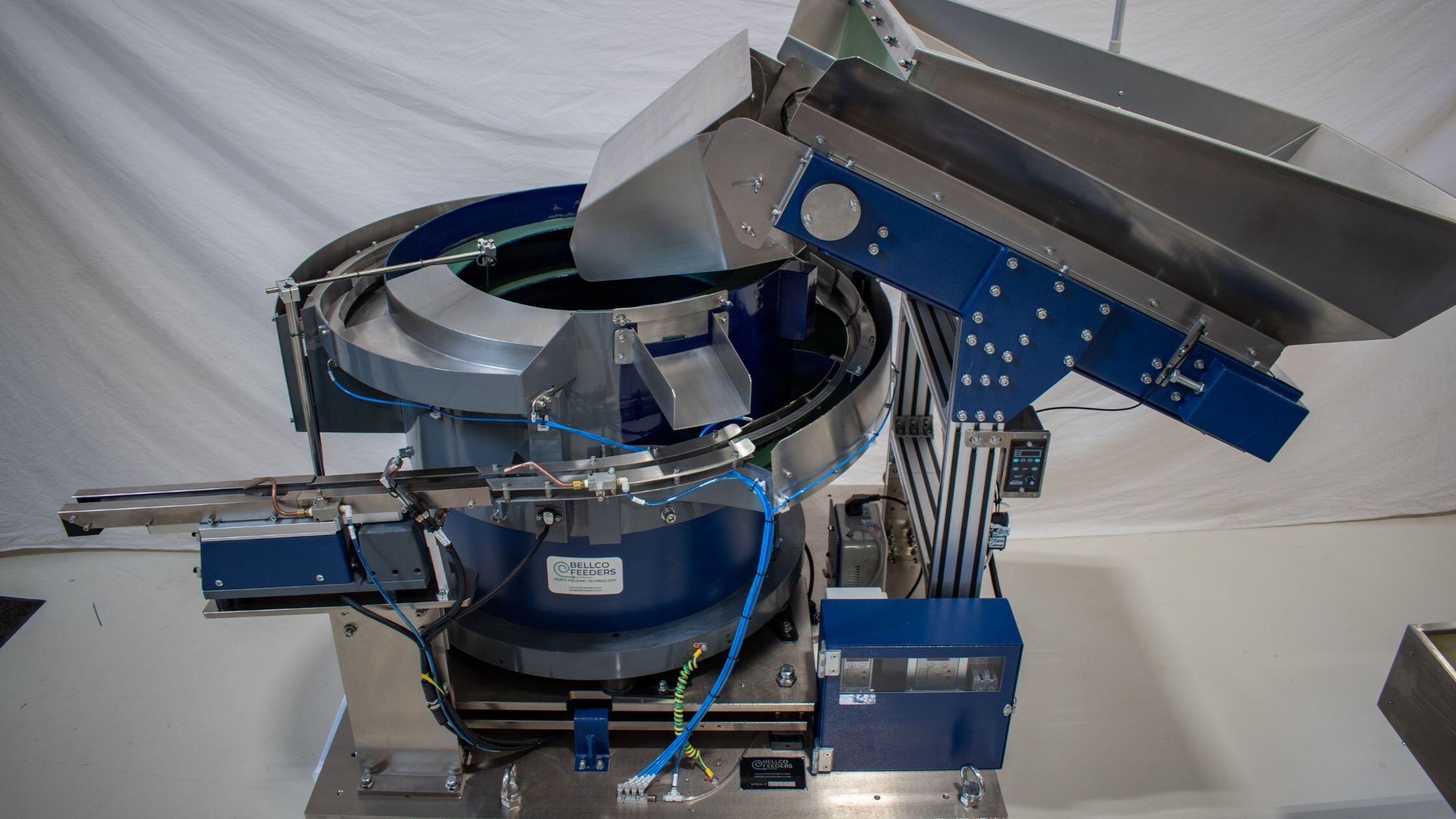

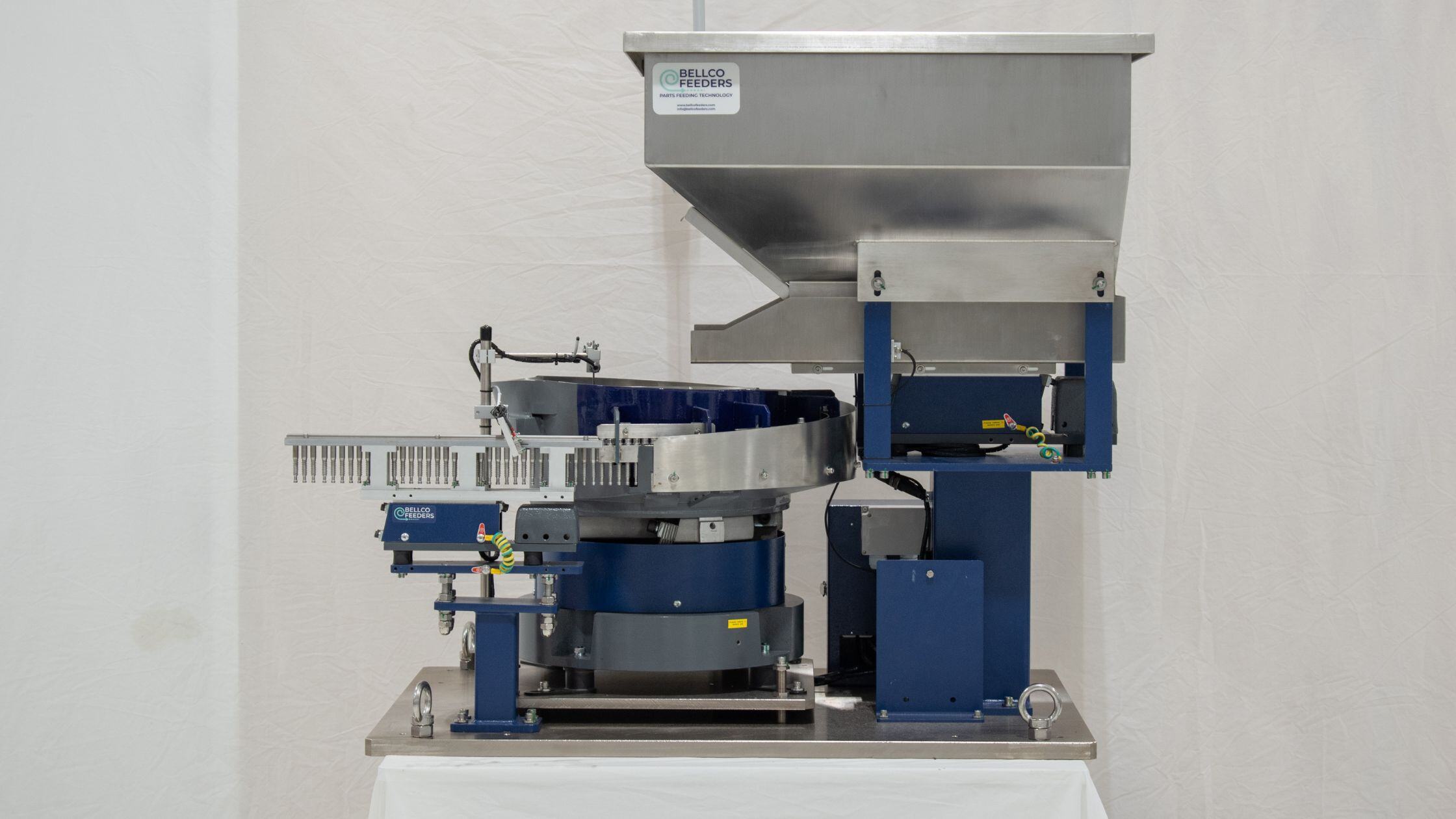

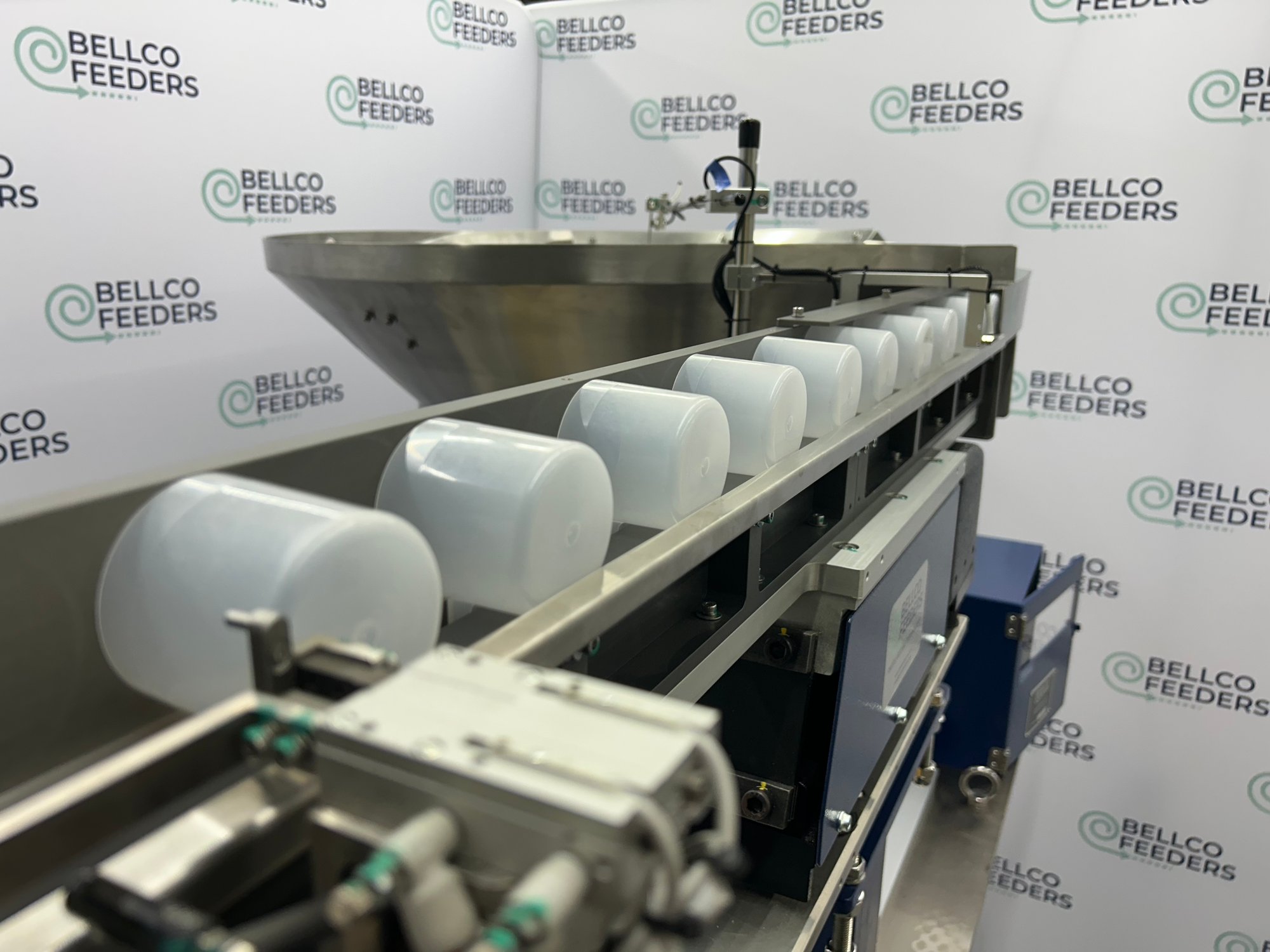

316 Stainless Steel Vibratory Feeder Bowl – Medical-Grade, 100 PPM Output

Two vibratory feeder bowls engineered from 316 stainless steel, offering superior corrosion resistance and hygienic performance to meet the stringent requirements of the medical and pharmaceutical industries. Designed specifically for cap feeding applications, this feeder delivers consistent, high-speed orientation and feeding at up to 100 parts per minute (PPM).

Key features include:

- Material: Constructed from 316SS for maximum durability, chemical resistance, and cleanroom compatibility.

- Performance: Optimized bowl geometry ensures reliable orientation and smooth feeding of medical-grade caps at 100 PPM.

- Hygienic Design: Crevice-free, polished surfaces for easy cleaning and sterilization, suitable for GMP-compliant environments.

- Custom Configuration: Tailored tooling and track design for precise handling of small or delicate components common in medical applications.

- System Integration: Compatible with downstream automation equipment such as cappers, vision systems, and robotic pick-and-place systems.

Ideal for high-throughput, contamination-sensitive applications, this feeder bowl provides a dependable solution for medical device assembly lines where accuracy, speed, and compliance are critical.

-Feb-03-2025-08-17-59-1147-PM.jpg?width=2000&height=1125&name=Both%20Bowls%20(Best)-Feb-03-2025-08-17-59-1147-PM.jpg)

%20(Best)-1.jpg?width=2000&height=1125&name=Close%20Up%20of%20Tooling%20(With%20Part)%20(Best)-1.jpg)

Food Processing & Packaging

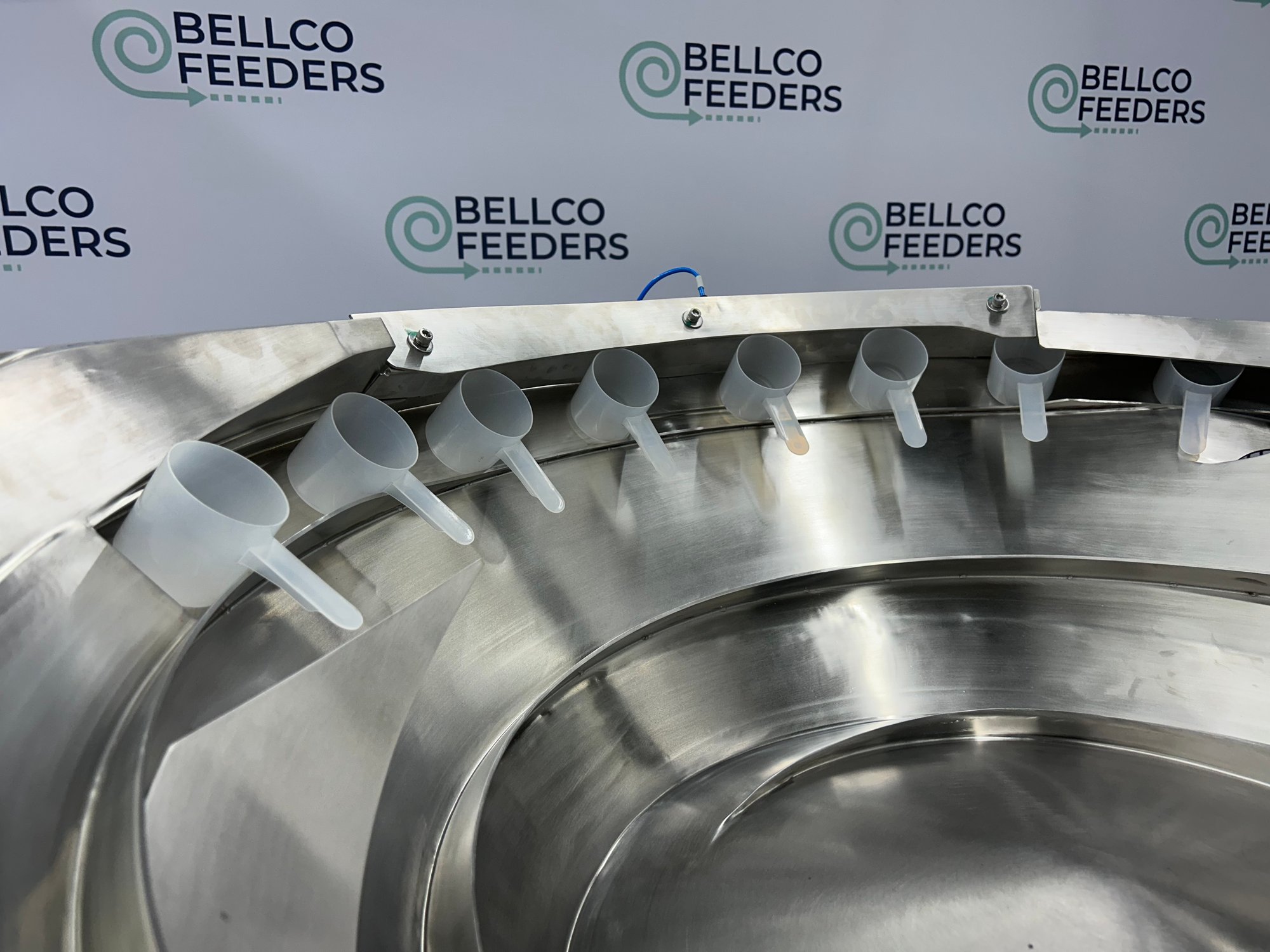

Stainless Steel Vibratory Feeder System – Food-Grade, 40 PPM Output

A food industry manufacturer required a reliable solution to feed medium-sized plastic scoops—commonly used in protein powder and supplement containers—into their packaging line at a steady rate of 40 parts per minute (PPM). Bellco Feeders engineered a vibratory feeder system that maintains consistent scoop orientation and smooth part flow, ensuring trouble-free operation and reducing downtime.

Key features include:

-

Performance: Optimized bowl geometry and precision tooling provide consistent orientation and feeding of plastic scoops at 40 PPM.

-

Jam-Free Design: End-of-track sensor paired with a two-finger escapement ensures accurate placement into containers without jamming or misfeeds.

-

Food-Grade Construction: Stainless steel build offers corrosion resistance, easy cleaning, and compliance with food safety standards.

-

System Integration: Designed to seamlessly plug into the customer’s existing automation, simplifying installation and minimizing downtime.

-

Reliable Operation: Built for continuous use in high-volume packaging environments, ensuring smooth, uninterrupted throughput.

This fully integrated feeder solution provides packaging manufacturers with a dependable, food-safe system that guarantees consistent scoop orientation, accuracy, and reliability—keeping production lines running at peak efficiency.

Automotive

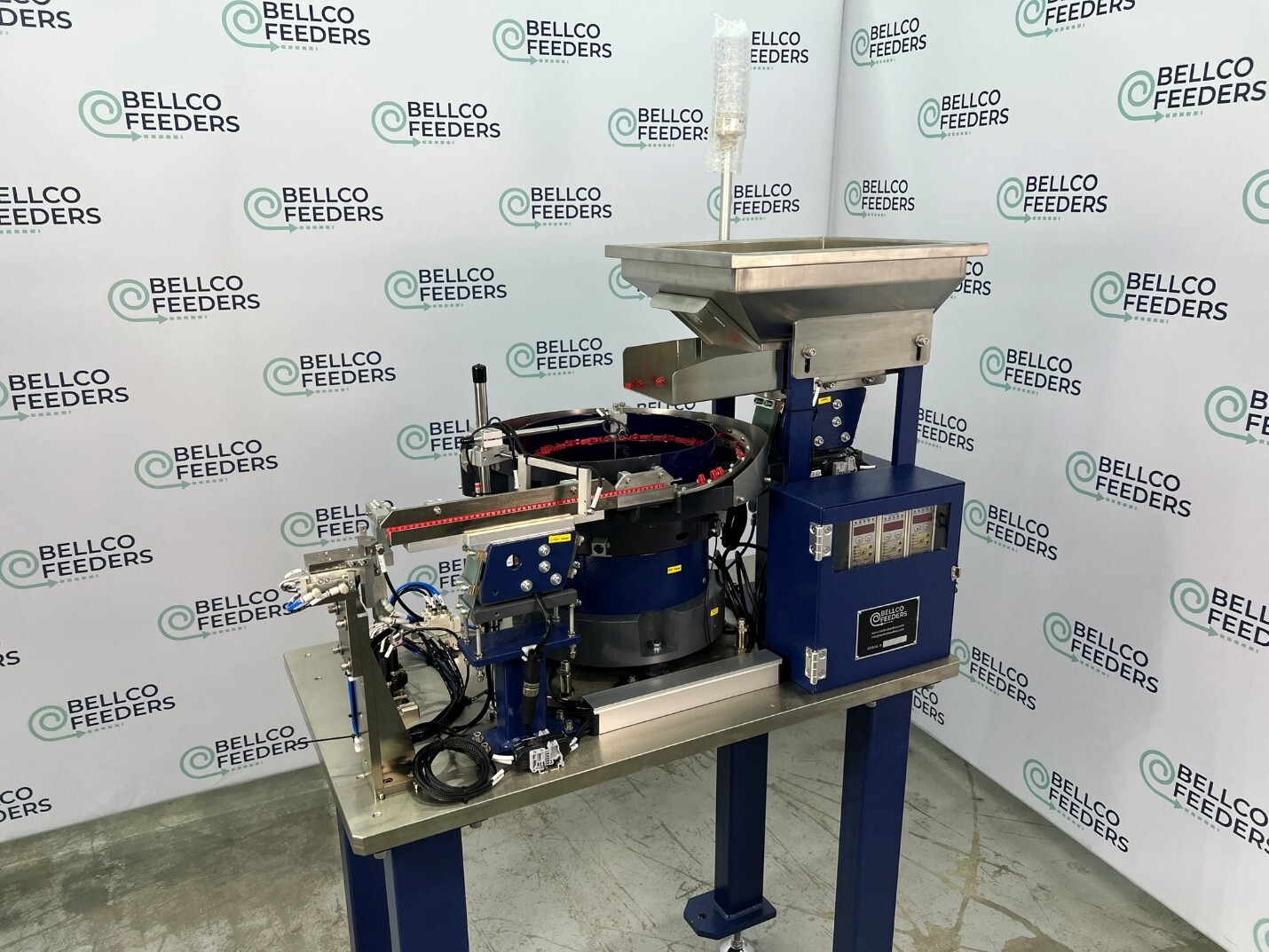

Hardened Steel Vibratory Feeder Bowl – Automotive-Grade, 55 PPM Output

Engineered for the demanding needs of automotive manufacturing, this feeder bowl orients and feeds plastic clips at up to 55 parts per minute (PPM). Precision tooling and optimized bowl geometry ensure consistent orientation, smooth flow, and jam-free operation, keeping production lines running without interruption.

Key Features:

-

Durability: Hardened tool steel with wear-resistant coatings for long service life.

-

Performance: Reliable orientation and feeding at 55 PPM.

-

Jam-Free Design: Custom tooling and track layout minimize misfeeds.

-

Heavy-Duty Build: Built for continuous 24/7 operation.

-

Custom Fit: Tailored to automotive clip and fastener applications.

-

Seamless Integration: Compatible with robotics, vision systems, and OEM automation.

This robust feeder delivers the speed, accuracy, and reliability Tier 1 suppliers and OEMs depend on.

Robotics & Integration

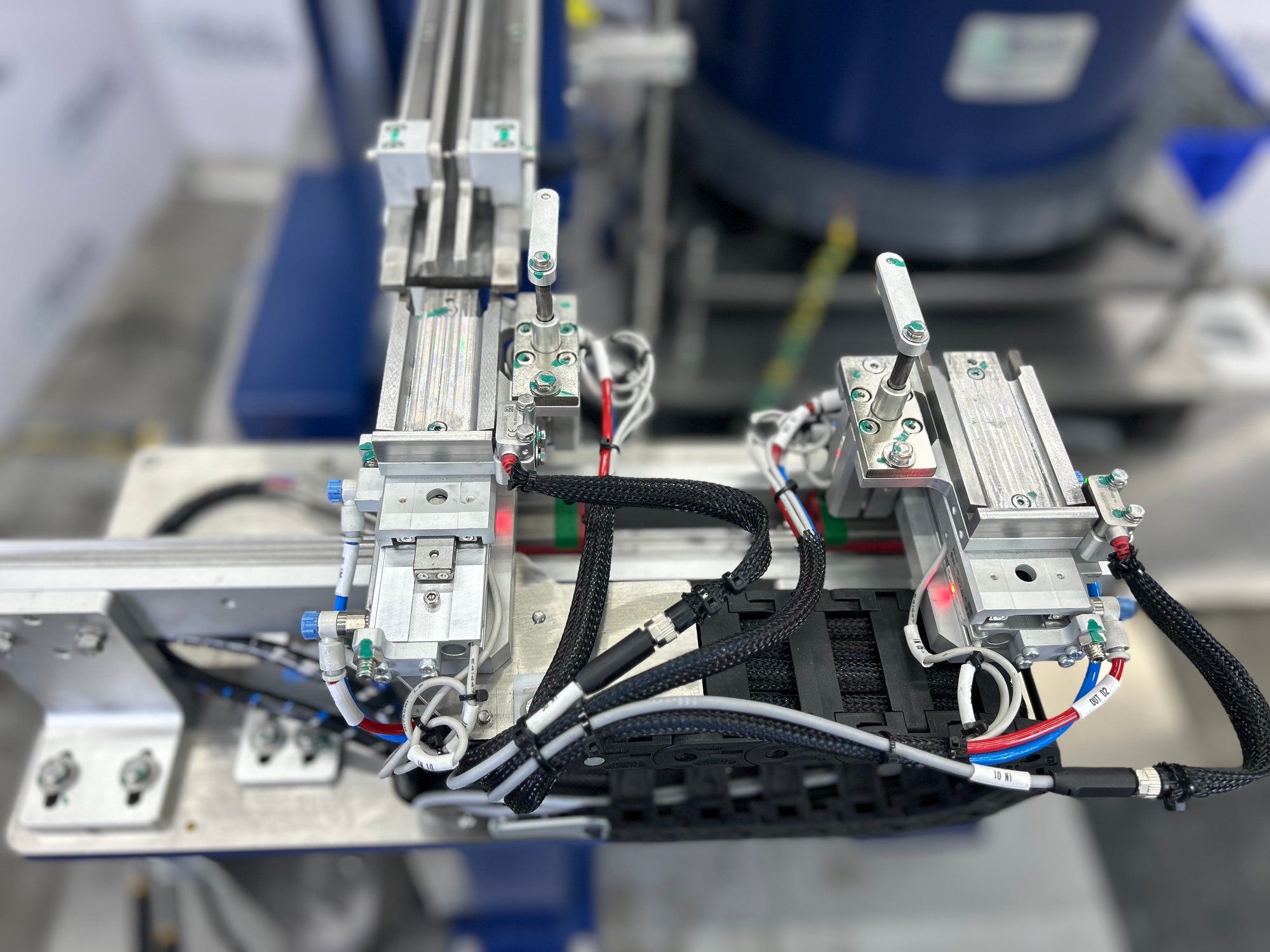

Robotics-Integrated Vibratory Feeder – Aluminum Retainers, 45 PPM

Bellco engineered a vibratory feeder system to orient and deliver aluminum retainers at 45 parts per minute, designed for seamless integration with robotic pick-and-place automation. Optimized tooling and bowl geometry ensure consistent orientation, while robust construction supports reliable operation in continuous production.

Key features include:

-

Consistent Orientation: Precision tooling and bowl design maintain reliable part positioning for accurate robotic handling.

-

Jam-Free Operation: Tailored track configuration minimizes misfeeds and prevents jamming, ensuring smooth throughput.

-

Robotics Integration: Designed for direct interface with robotic arms and automation controls for precise, high-speed pick-and-place.

-

Durability: Built from hardened materials to withstand continuous use in demanding production environments.

This system provides manufacturers with a dependable feeder solution that guarantees accuracy, reliability, and efficiency in automated assembly lines.

Automotive

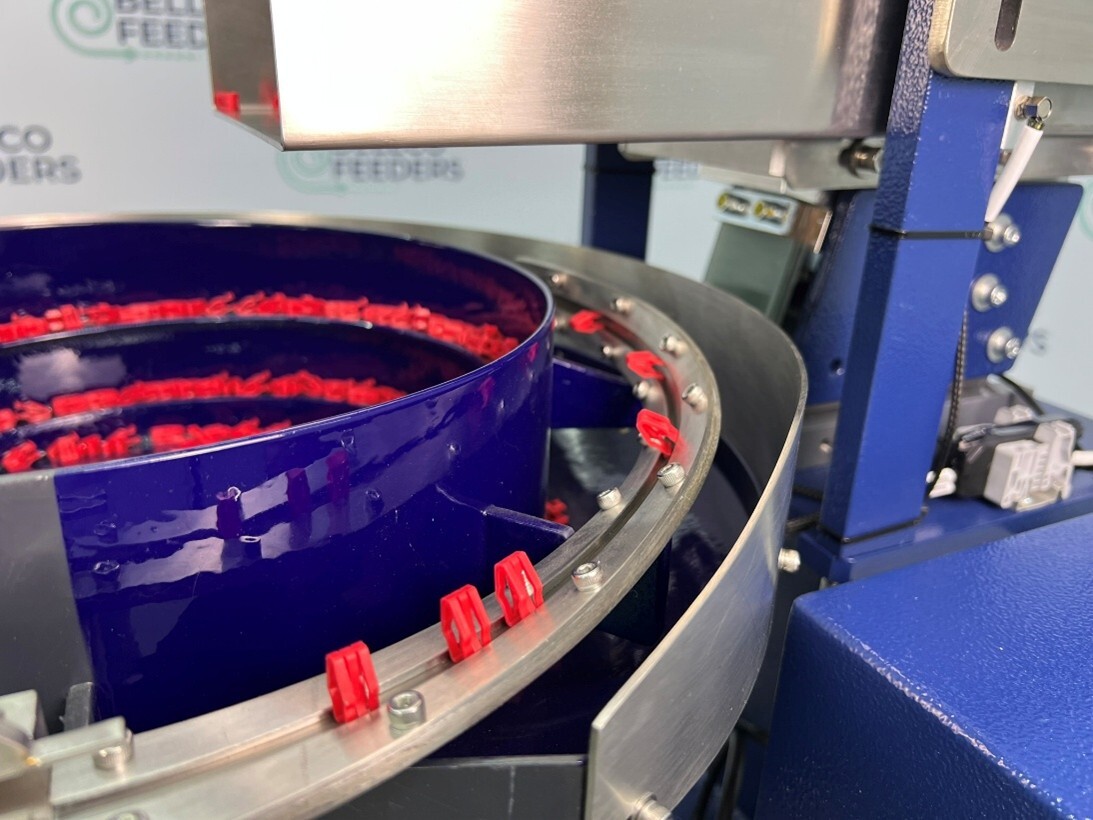

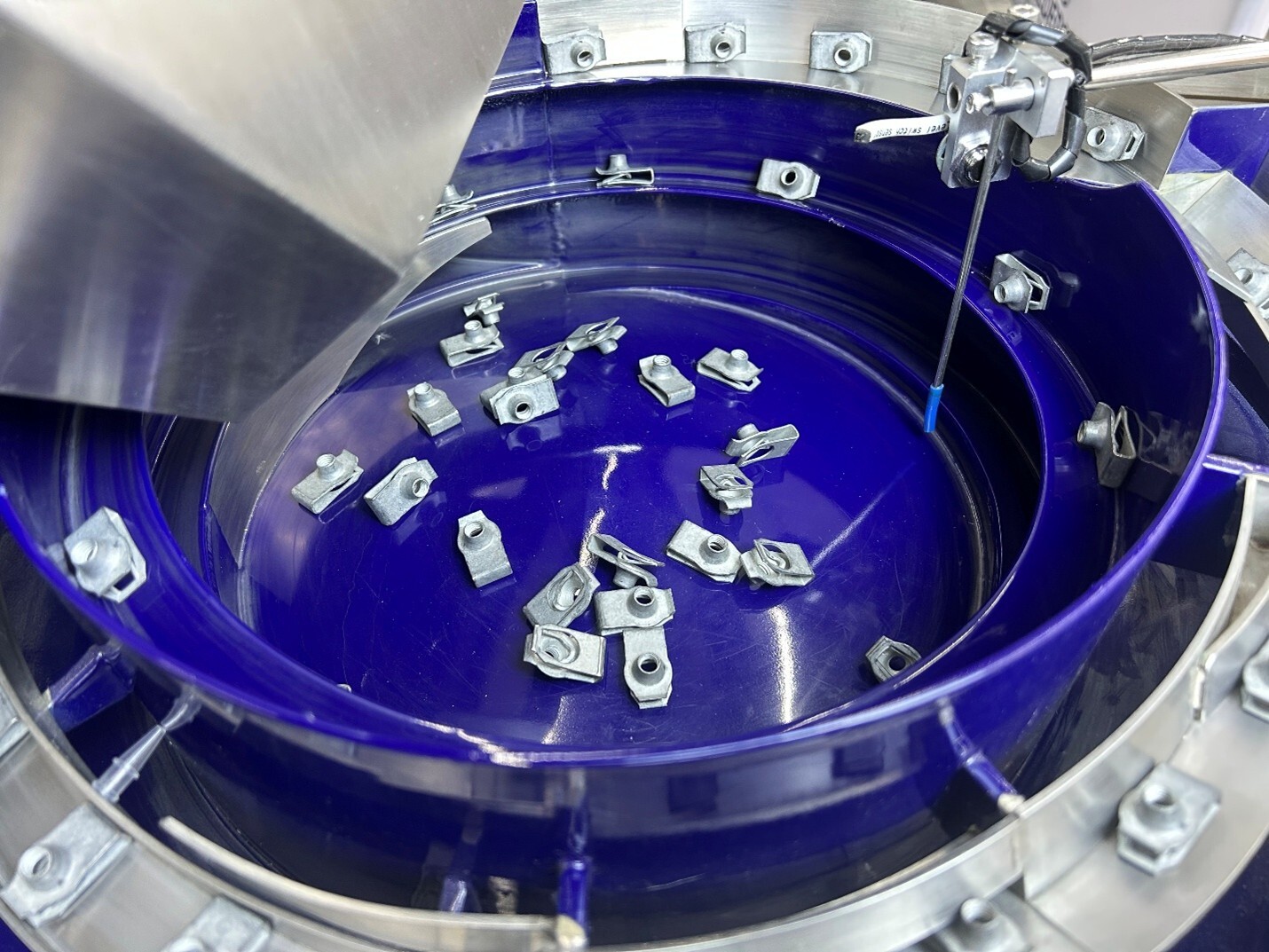

Vibratory Feeder System – Automotive Metal Clips, 45 PPM

Bellco developed a vibratory feeder solution for GM to reliably orient and feed small metal clips into their assembly process at 45 parts per minute. The system was designed with precision tooling and optimized bowl geometry to ensure consistent orientation and smooth part flow without jamming, supporting uninterrupted high-volume production.

Key features include:

-

Performance: Feeds and orients small automotive metal clips at 45 PPM with reliable accuracy.

-

Jam-Free Design: Tailored track and escapement minimize misfeeds and ensure smooth, consistent flow.

-

Durability: Heavy-duty construction supports continuous use in demanding automotive assembly environments.

-

Custom Engineering: Tooling designed specifically around GM’s metal clip geometry for secure handling.

-

System Integration: Built to interface seamlessly with GM’s downstream automation and assembly equipment.

This feeder system provides GM with a dependable, high-precision solution that guarantees consistent orientation, smooth integration, and reliable operation in mission-critical automotive production.

Vibratory Bowl Feeders set the Standard for Sorting, Feeding, and Orienting Parts

Vibratory feeder bowls are the backbone of automated manufacturing processes, offering a reliable and efficient method for sorting, feeding, and orienting components. These systems are essential in high-speed production environments where precision and consistency are key.

How Vibratory Bowl Feeders Work

Bulk Part Introduction: Parts are initially loaded into the vibratory feeder bowl from bulk containers. The bowl’s design allows for continuous and seamless feeding of these parts into the system.

Vibration Tuning: The bowl is equipped with a specialized vibration mechanism that is finely tuned to control the movement of parts. This vibration causes the parts to travel along a carefully engineered path, interacting with various tooling components.

Sorting and Orienting: As the parts move around the bowl, they pass through different tooling stations designed to sort and orient them. This process ensures that each part is positioned correctly before exiting the feeder. The result is a continuous flow of accurately oriented parts, ready for the next stage of production.

Exit and Integration: Once sorted and oriented, the parts are directed to the exit point of the bowl. From here, they are fed into the production line or assembly process, precisely aligned according to the required specifications.

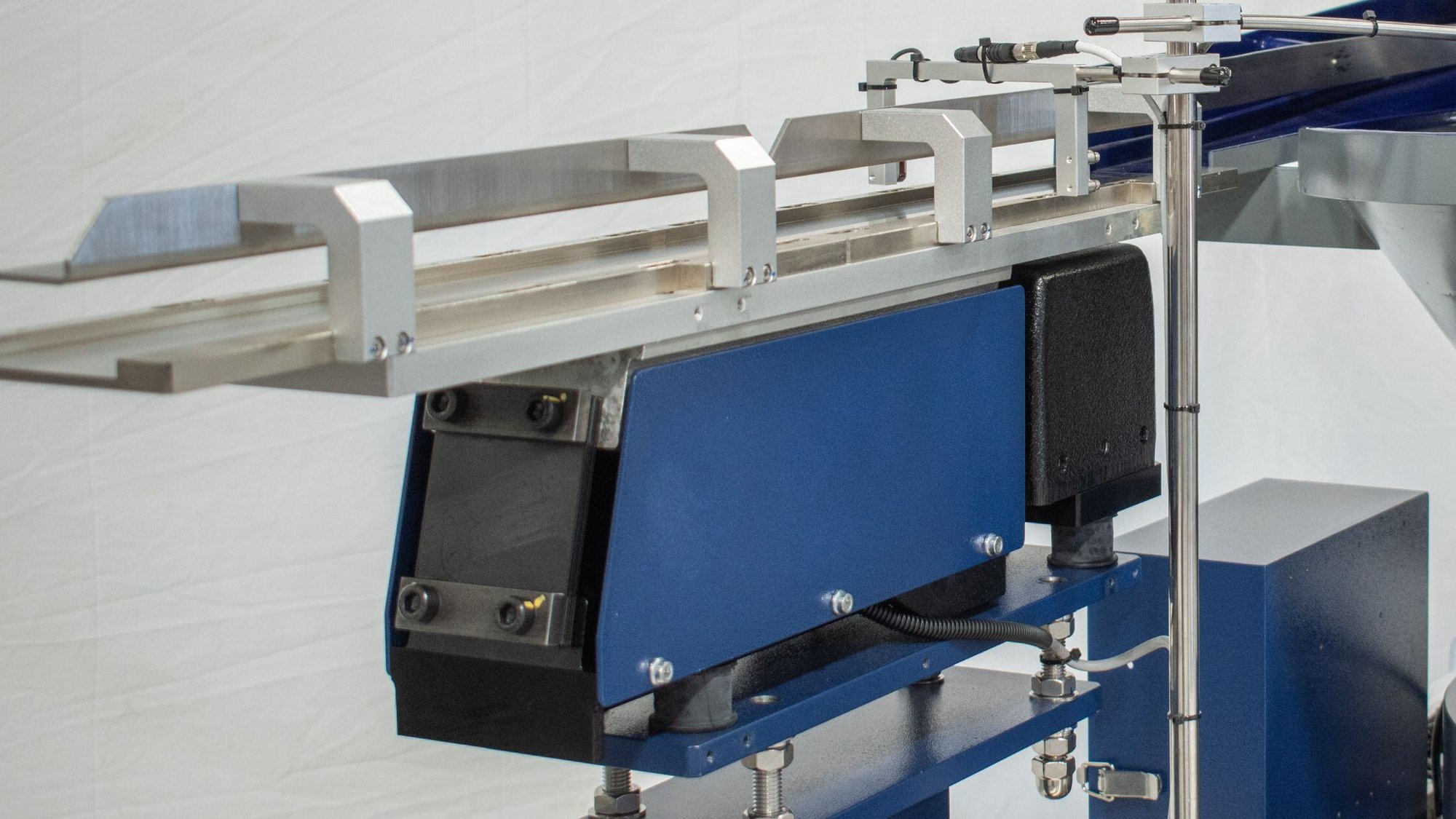

Linear Feeders

Linear feeders are commonly incorporated into our bowl feeder package.

The main purpose of a linear feeder is to move parts in a line to exit the feeder bowl system. This type of feeder can move the parts using vibrations and/or air guidance to any desired location away from the bowl.

A linear feeder also creates an accumulating buffer, ensuring a part is always ready to be unloaded and aids in feeder rate and output.

Feeder Accessories

Why Choose Bellco Feeders?

At Bellco, we're dedicated to providing top-of-the-line vibratory bowl feeding systems that deliver exceptional performance at highly competitive prices. Our systems are designed to handle a diverse range of part geometries and manufacturing needs, so you get a solution tailored to your specific requirements.

-

Expert Design and Engineering: With years of experience in designing and implementing vibratory bowl feeders, our team has the expertise to create custom solutions that meet the highest standards of quality and efficiency.

-

Custom Solutions for Every Need: We understand that every manufacturing process is unique. That’s why we offer customizable feeding systems to accommodate various part shapes, sizes, and production demands.

-

Cost-Effective Excellence: Our commitment to delivering high-quality systems at ultra-competitive prices means you get the best value for your investment without compromising on performance.

We pride ourselves on our ability to provide innovative and reliable feeding solutions that enhance your manufacturing operations. Contact us today to learn how our vibratory bowl feeders can optimize your production processes and drive efficiency.

Frequently Asked Questions

Ready to Get Started?

We understand the importance of quality components, competitive pricing and on-time deliveries. Our team is available to answer your questions and provide a quote for your custom parts feeding solutions.