Consumer Products Industry

We have experience manufacturing parts feeding systems for the Consumer Products Industry.

Streamline Your Production with Precision and Efficiency

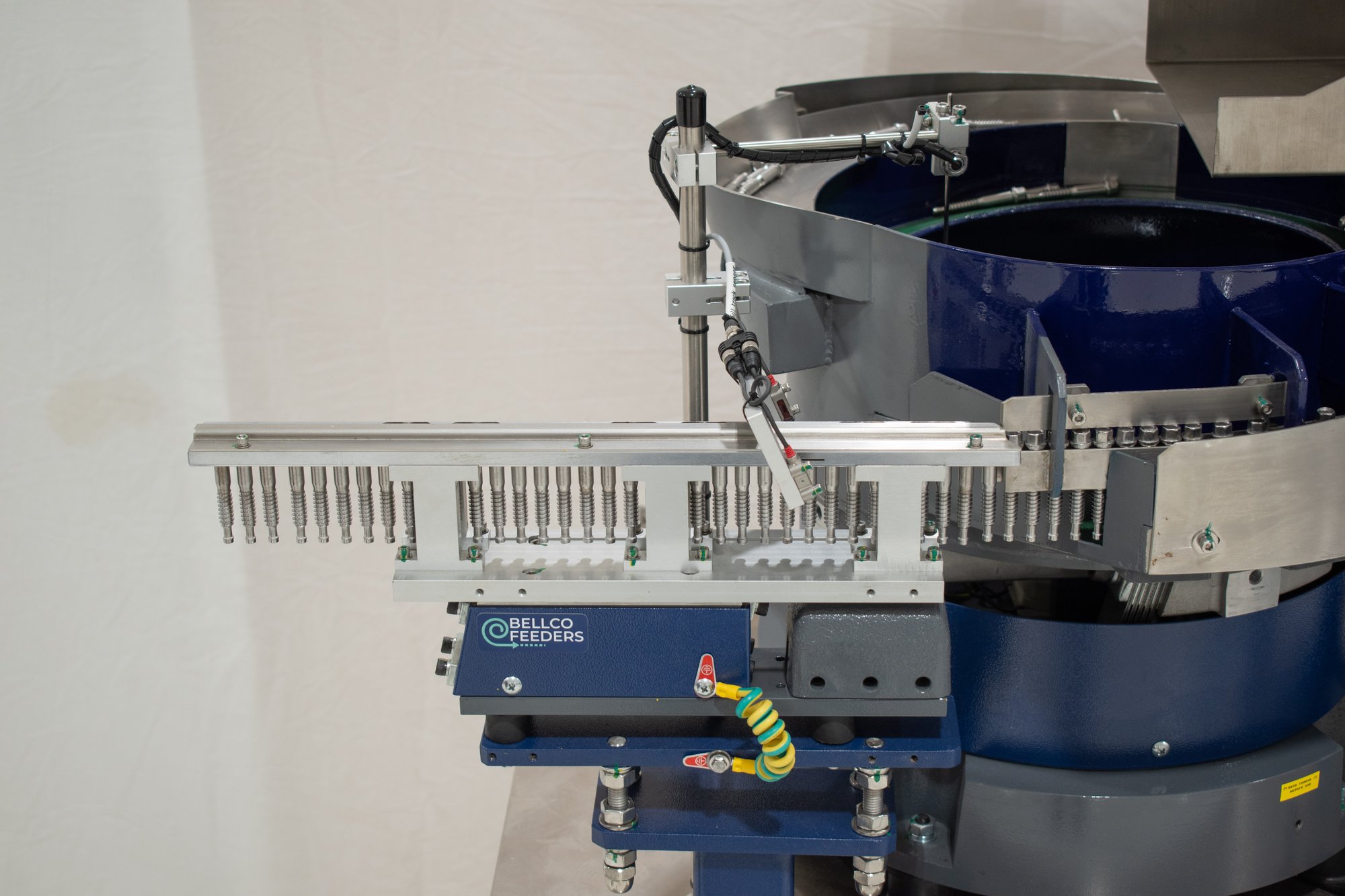

In the fast-paced consumer products industry, efficiency and precision are crucial to maintaining a competitive edge. Vibratory bowl feeders are essential components in automated production lines, designed to enhance operational efficiency and ensure high-quality output. At Bellco Feeders, we specialize in delivering advanced vibratory bowl feeders tailored to meet the specific needs of the consumer products sector.

Over the past few years we have seen a new demand for consumer product goods, becoming one of the main drivers of conveyor systems and other automation technology. It is no surprise that fast-moving consumer goods (FMCG) companies are turning to technology to overcome challenges and take advantage of market opportunities.

Our team understands how challenging it is to operate in a highly volatile environment.

Why Choose Vibratory Bowl Feeders?

Vibratory bowl feeders offer unparalleled benefits for the consumer products industry, including:

-

Increased Production Speed: Vibratory bowl feeders ensure a continuous and consistent flow of parts or components, significantly boosting production rates. Their high-speed operation helps keep up with the demands of large-scale manufacturing while maintaining precise control.

-

Enhanced Accuracy and Consistency: These feeders are designed to handle parts with high precision, reducing errors and minimizing variability in product assembly. This ensures that each component is placed accurately, resulting in a more reliable final product.

-

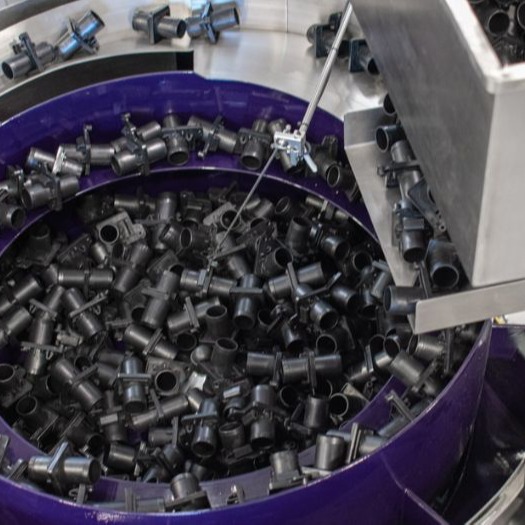

Versatility in Handling Various Products: Whether you're working with small, intricate parts or larger components, vibratory bowl feeders can be customized to handle a wide range of items. This adaptability makes them ideal for diverse consumer products, from electronics to household goods.

-

Reduced Labor Costs: By automating the feeding process, vibratory bowl feeders reduce the need for manual handling, leading to lower labor costs and a more streamlined production line. This automation also reduces the risk of workplace injuries associated with manual handling.

-

Efficient Space Utilization: Vibratory bowl feeders are compact and designed to fit seamlessly into existing production lines. Their efficient use of space helps maximize your production area and optimize overall workflow.

Our automated solutions keep you one step ahead of your competition in consumer goods manufacturing.

We are a team of engineers with over 20 years of experience who have been pioneering Industry 4.0 development. We can bring you knowledge and expertise about the right parts feeding and material handling solutions for your operations.

Appliance Industry

In conjunction with our experience in the consumer products industry, we also supply vibratory bowl feeders, step feeders and other custom systems to manufacturers in the appliance industry. Our custom part-feeding systems can help you automate your production line and stay on top of today's modern appliance manufacturing trends.

From bowl feeder automation to custom parts escapement, we can offer you a full line of configurable manufacturing products to integrate into your application. Improve the speed, safety, and quality with which you produce appliances, such as refrigerators, washing machines, washers, stoves, etc.

High-Performance of Bellco Feeders

As a consumer goods manufacturer, you can rely on us for a custom, high-performance parts-feeding solution that offers an easy setup and configuration. Share with us your specific requirements - such as product variants, bulk hopper capacity, product feed rate, component escapement, singulation unit, product sense, and discharge height - and we will design a custom automated feeding system that meets your application's specifications.

We're experts in vibratory bowl feeders and offer complete solutions with industrial-grade hopper feeders, linear tracks, and custom parts escapements.

FMCG are items that are traded rapidly by consumers and require routine replacement, such as food, tobacco, cosmetics, and household cleaning products. We will offer a process automation solution according to your products’ details and optimum support for your next feeding part system.

Featured Case Study

Child Proof Caps for an Insect Repellant Product

Bellco designed and manufactured three custom vibratory feeder bowls and bulk parts hopper to feed an automated assembly machine that produces insect repellant products. The three products were different sizes and geometries and all needed to be fed at the same rate.

Products:

- child proof caps

- inspect repellant container

- fabric wick

Ready to Get Started?

We understand the importance of quality components, competitive pricing and on-time deliveries. Our team is available to answer your questions and provide a quote for your custom parts feeding solutions.