Parts Feeding for the Food and Beverage Industry

Bellco Feeders designs and manufactures custom parts feeding systems for the food and beverage industry

Bellco Feeders designs and manufactures food-grade parts feeding systems for the food and beverage industry. As global demand rises with changing consumer habits, food and beverage manufacturers rely on automation for efficient production management, quality control, and consistent throughput.

Our high-speed vibratory feeding systems help food and beverage manufacturers streamline operations, maintain consistent part flow, and increase productivity across packaging and processing lines.

Our food-grade, compliant vibratory parts feeding systems reduce human error, optimize labor efficiency, and deliver rapid processing times with measurable cost savings.

We collaborate with your team to design a custom parts feeding system that solves your specific challenges in food and beverage manufacturing. With over 20 years of engineering experience in automation and material handling, Bellco delivers reliable, hygienic systems that meet your production needs.

Our Process

Reach out to us to evaluate how our vibratory bowl feeders, inline feeders, and flex feeding solutions can improve your plant’s output and efficiency.

Our automated feeding systems reduce operational costs and deliver a fast ROI. Each project is supported by a dedicated Bellco engineer and team, providing a full line of feeder accessories and spare parts to ensure your manufacturing process runs smoothly.

Featured Case Study

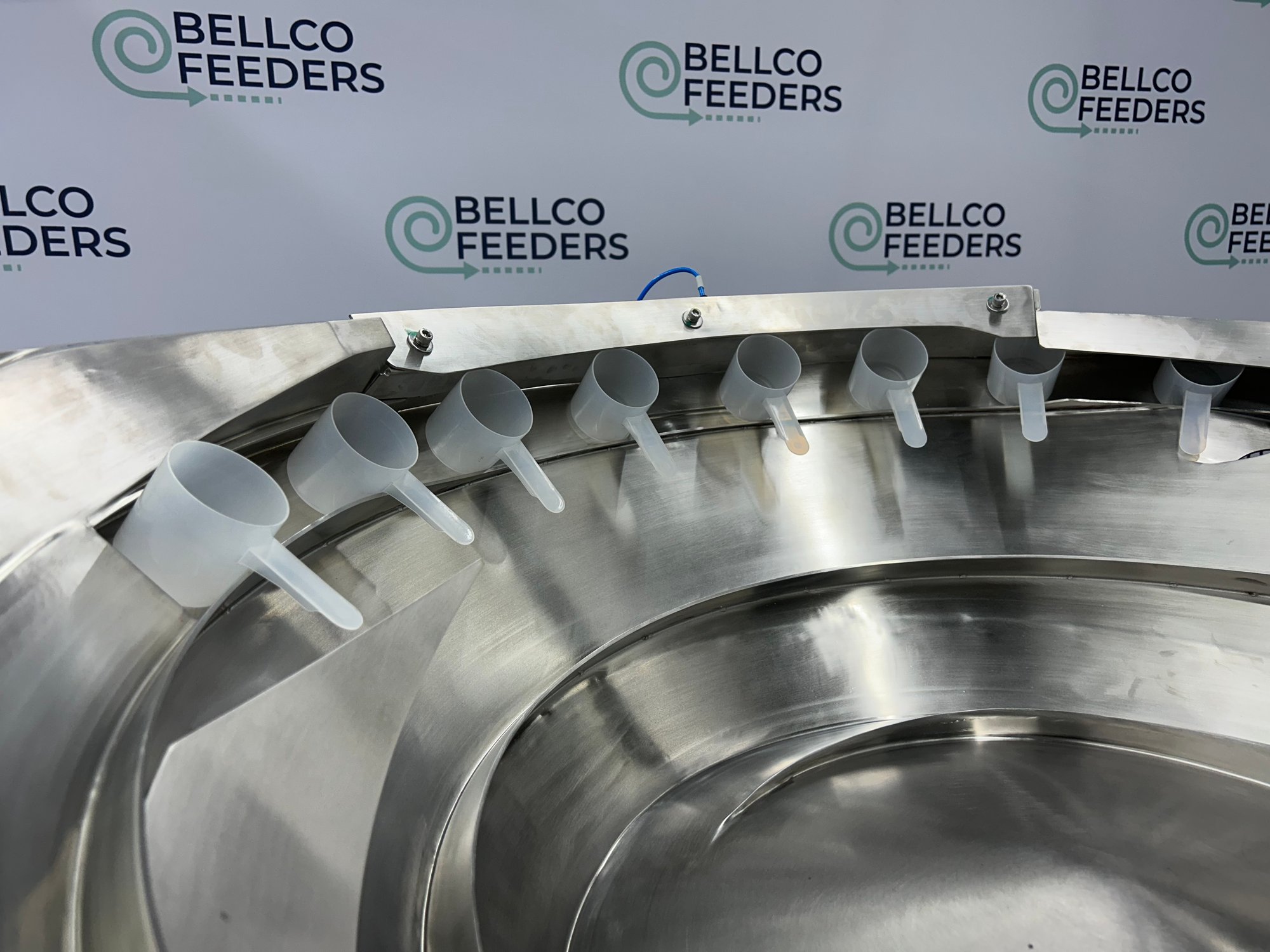

Scoop Feeder for Food-Grade Parts Feeding Line

A food industry manufacturer needed a reliable way to feed medium-sized plastic scoops—like those used in protein powder containers—into their packaging line at a consistent rate of 40 parts per minute. The main priorities of the project were ensuring the system was food-grade, and able to be integrated seamlessly into an existing custom machine.

The Bellco team engineered a custom vibratory feeder bowl system using 304 polished stainless steel. The solution included an elevated conveyor hopper for hands-free loading, a vibratory bowl feeder, and an end of track sensor paired with a two-finger escapement for seamless integration.

Ready to Get Started?

Looking for a food-grade parts feeding system for your production line? Our team can provide a tailored quote and recommendations based on your unique application.