How to Streamline Your Production: Ergonomics and Automation

In today's manufacturing industry, the need for automation is ever increasing. With this increase in automation, it's essential to consider the ergonomics of production processes. In this article, we'll discuss how vibratory bowl feeders can be used to streamline production while also making the workplace safer and more efficient.

Introduction to Ergonomics in Industrial Automation

Ergonomics is the study of how people interact with their environment. In industrial automation, ergonomics is concerned with how to design workstations, tools, and machines so that workers can safely and effectively perform their tasks.

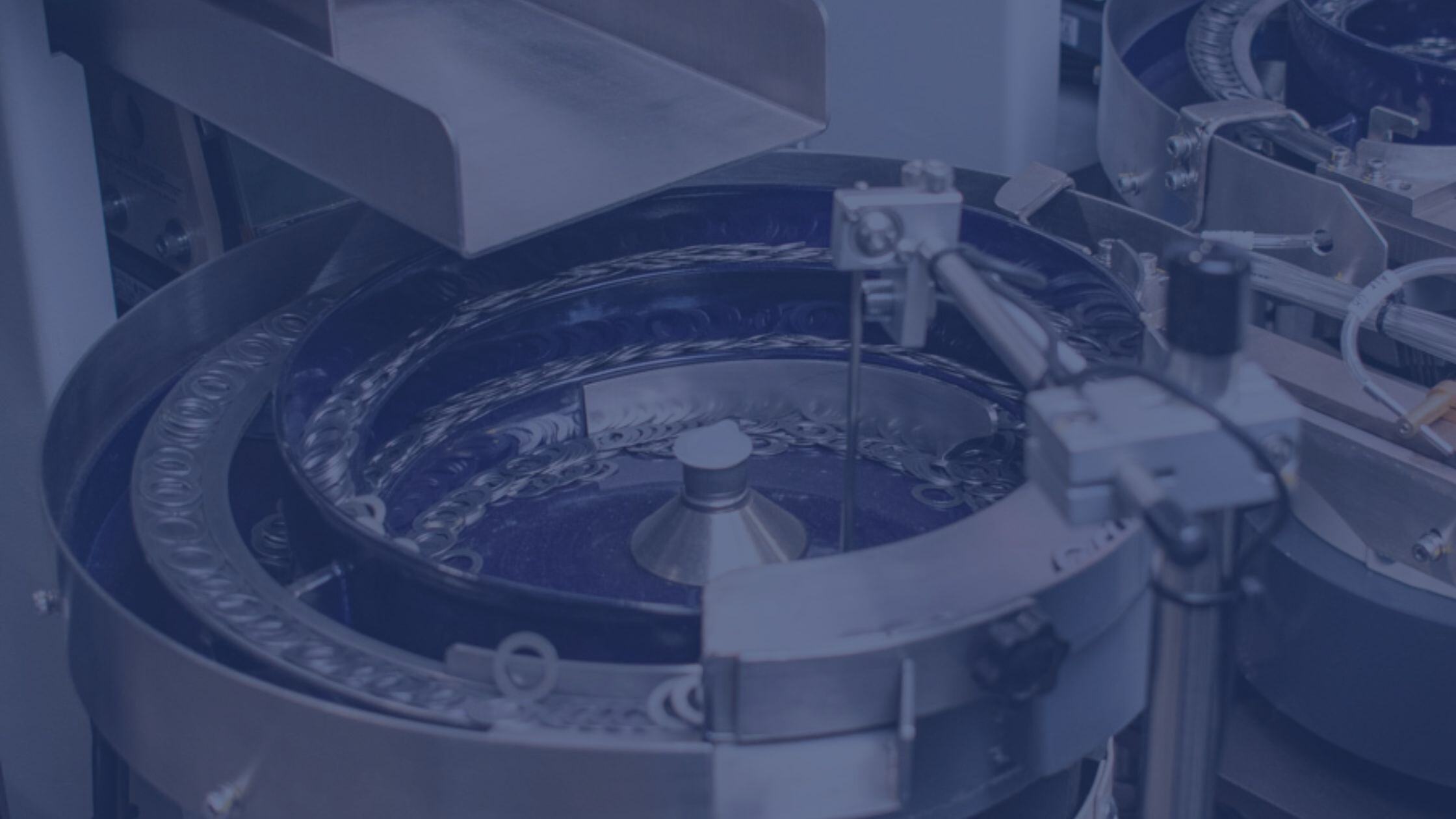

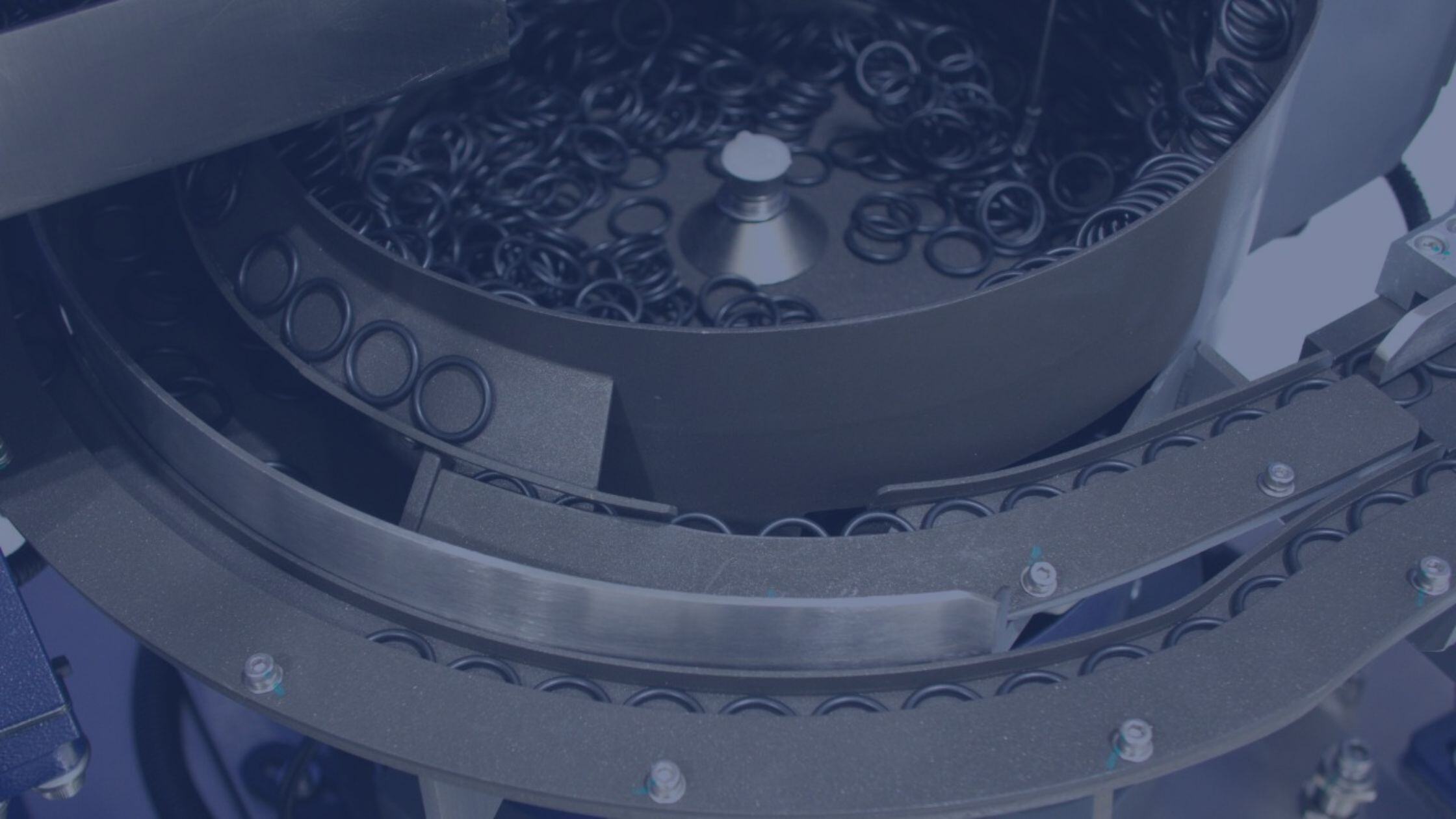

Vibratory bowl feeders are one type of equipment that can be used to improve ergonomics in industrial settings. These devices are designed to feed small parts into machinery such as assembly lines or automated machines. By using a vibratory bowl feeder, workers can avoid having to bend over or reach for parts, which can help reduce back strain and other injuries.

Ergonomic Considerations in a Manufacturing Setting

When designing a manufacturing process, it is important to consider the ergonomics of the workstation. This includes the layout of the equipment, the height of the work surface, the reach of the operator and the weight of the parts. By taking these factors into account, you can design a production line that is both efficient and comfortable for your workers.

One way to improve the ergonomics of your production line is to use vibratory bowl feeders. When paired with bulk part hoppers, these devices can be used to orient and feed parts to an assembly line, which reduces the need for workers to bend, lift or reach for components. Vibratory bowl feeders can also be equipped with sensors that detect when a part is misaligned or missing, which helps to reduce errors in your manufacturing process.

Drawbacks to Manual Labor

One of the most important aspects of any production line is efficiency. When each task in the production process is carried out quickly and efficiently, the overall output of the line increases. For years, manufacturers have relied on manual labor to load, assembly and produce products.

While there are some advantages to carrying out tasks manually, it does have its drawbacks. One of the main physical implications of repeated manual tasks is musculoskeletal disorders (MSDs). MSDs can develop over time as a result of repetitive motions and poor posture. They can cause pain, stiffness and weakness in the muscles, joints and tendons.

To help reduce the risk of developing MSDs, it is important to take regular breaks from the task and to practice good ergonomic principles when carrying out the task. This includes maintaining a neutral position with the wrists and avoiding awkward positions. It is also important to use tools which are designed to reduce strain on the body, such as anti-fatigue mats or ergonomic workstations.

How Automation Can Create a Safer Workplace

Automation can help to create a safer workplace by reducing the need for workers to perform tasks that may be hazardous. Vibratory bowl feeders are one type of automation that can be used in manufacturing processes. For example, vibratory bowl feeders can be used to automatically feed and orientate small parts, which reduces the risk of injuries caused by manual handling. Especially when parts may be heavy, sharp or difficult to manually grip and orient.

In addition, automation can help to improve working conditions by providing a more consistent and controlled environment. This can help to reduce exposure to hazards such as noise and dust, and can also help to improve workstation ergonomics.

Safety Tips for Working with Vibratory Bowl Feeders

Using automated manufacturing equipment doesn't eliminate the need for skill and careful operators. When working with vibratory bowl feeders, there are a few safety tips to keep in mind. First, always wear proper PPE including gloves, safety glasses, and hearing protection. Second, be aware of your surroundings and keep clear of moving parts. Third, never reach into the bowl while the feeder is running. Fourth, make sure the area around the feeder is free of trip hazards. Finally, if you need to adjust or service the feeder, always shut off power and disconnect from the power source before proceeding.

Conclusion

Ergonomics and automation are essential for any production line, and vibratory bowl feeders can help you streamline your processes. They provide a safe, reliable way to automate the feeding of small parts into machinery, allowing you to improve both efficiency and accuracy. If you're looking for an effective way to get the most out of your production process, consider investing in a vibratory bowl feeder system today.