Case Study: Feeding small plastic clips for medical device assembly

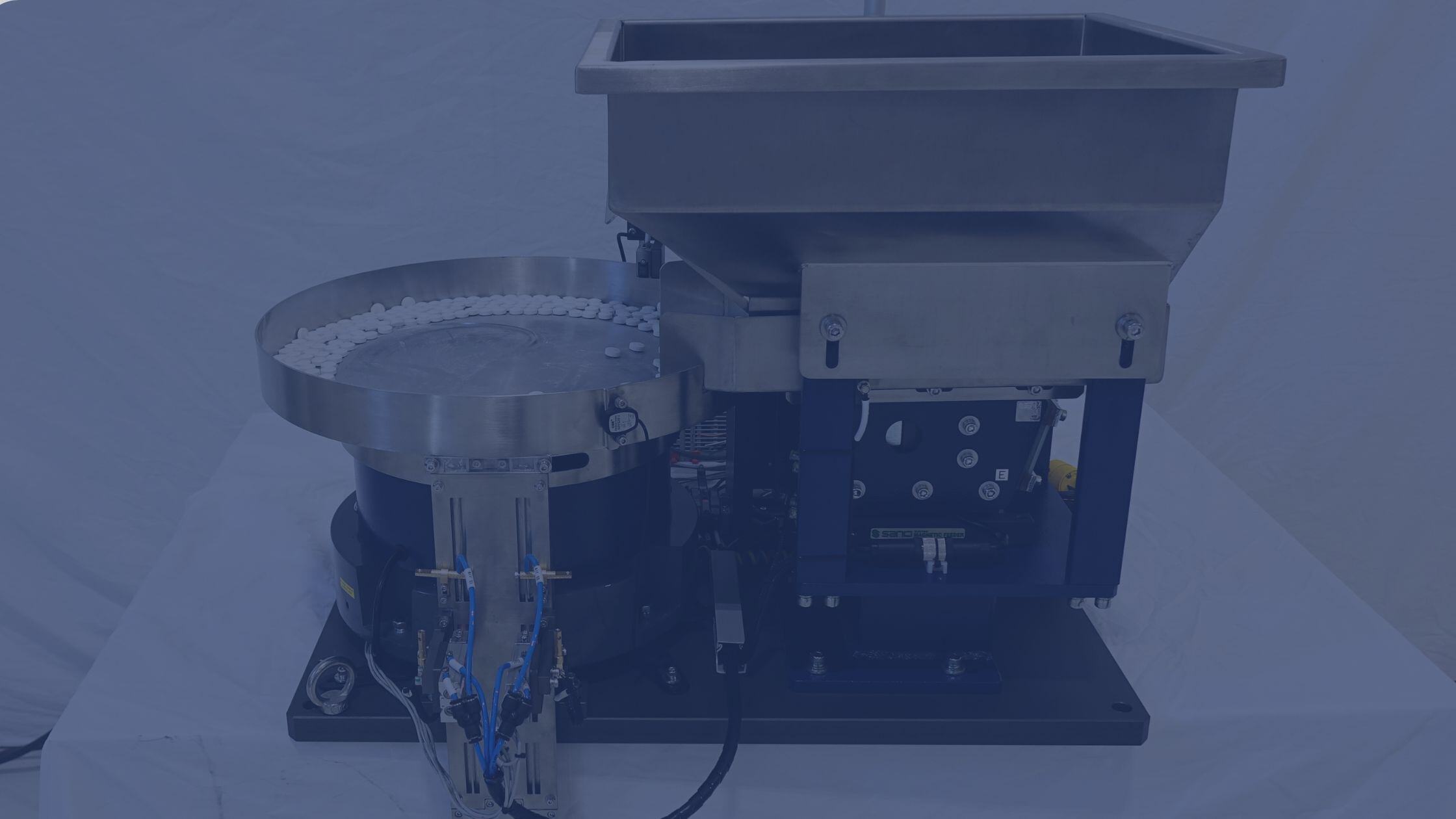

Bellco Feeders developed a vibratory bowl system to reliably feed and orient small plastic clips for a high-speed automated production environment.

| Industry | Medical device manufacturing |

| Rate | 25-30 PPM |

| Components |

Vibratory bowl feeder Bulk parts hopper (1-hour run-time) Linear track Sound enclosure |

Project Overview

An automated parts feeding solution was required for feeding small plastic clips in a medical device assembly line. These clips are challenging to feed and orient properly, as the slot must be leading and facing up. The Bellco team designed a vibratory bowl feeder that feeds and orients the clips for robotic pick-and-place operations, and is ready for seamless integration into a high-speed automation environment.

System Overview

Clips enter a 450mm hard-anodized aluminum vibratory feeder bowl via a bulk parts hopper. Instead of a traditional rotary escapement, orientation is achieved using integrated blow-off nozzles and fiber optic sensors mounted inside the bowl.

Clips are then guided along a 355.6mm linear track and presented in the correct, face-up orientation for pick-up. A 23mm nickel-plated ground steel baseplate ensures system durability.

A Keyence sensor is included for shortage detection and to ensure optimal parts flow. SMC air fittings, a PNP CUH variable frequency digital controller, and a fully-wired, lockable control box make integration into modern assembly lines easy.

This vibratory feeding system also includes a full sound enclosure to reduce noise for the safety and efficiency of the operators who work on the line.

Optional Escapement

An escapement could also be added to this system upon request. Bellco's recommendation for this system is a side shuttle escapement, which would provide consistent singulation and robot-ready presentation. This would be especially beneficial in high-speed automation cells.

Typical lead time is 12–14 weeks from order to shipment.

Instead of a rotary escapement, this system uses strategically placed blow-off nozzles and fiber optic sensors inside the bowl to orient parts accurately, reducing mechanical complexity and maintenance needs.

Yes. This system includes features like a Keyence sensor for parts flow monitoring, a PNP CUH variable frequency controller, and a fully wired control box — all designed for seamless integration into high-speed, robot-assisted medical device assembly lines.