Parts Feeding for the Automotive Industry

Custom Automotive Parts Feeding Systems

Enhancing Efficiency and Precision in Automotive Manufacturing

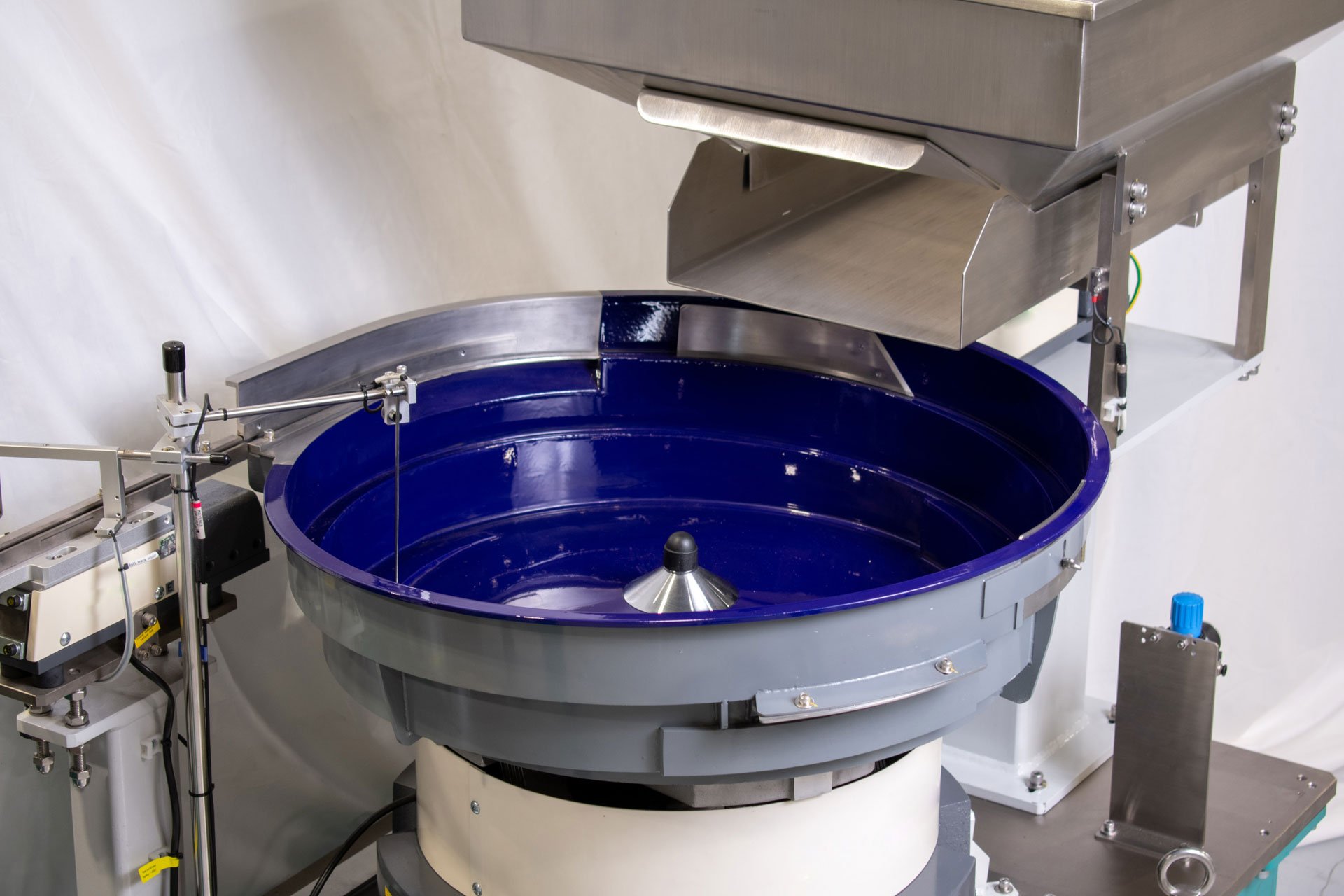

Vibratory bowl feeders are essential in the automotive industry, where efficiency, accuracy, and reliability drive productivity. At Bellco, we design high-performance feeding systems that support the high-volume production and complex assembly required for automotive manufacturing.

As electric vehicle (EV) adoption grows, battery technology advances, and customization rises, OEMs and Tier 1 manufacturers must adapt quickly, despite ongoing labor shortages. Our automation solutions help streamline operations, improve workplace safety, and maintain throughput across evolving automotive production lines.

Drive innovation faster and more efficiently with our solutions in the automotive industry.

Vibratory bowl feeders are used in a wide range of applications within the automotive industry, including:

Assembly Line Operations: Precisely orienting fasteners like bolts, nuts, washers, and clips for smooth, automated assembly.

Part Sorting and Handling: Automating the orientation of components to reduce manual labor and increase accuracy.

Component Feeding: Supplying a continuous flow of parts to robots and assembly stations to maximize efficiency.

Quality Control: Enabling accurate placement and inspection to maintain strict quality standards.

Benefits of Bellco Feeders

At Bellco Feeders, we understand that every automotive production line has unique requirements. Our team of experts is dedicated to designing and delivering custom vibratory bowl feeders that perfectly match your specific needs. From initial consultation to installation and ongoing support, we are committed to providing solutions that enhance your manufacturing processes and support your business goals.

Featured Case Study

Spring Feeder for Automotive Component Assembly Machine

Bellco Feeders designed and manufactured a vibratory bowl feeder with a large hopper and a linear track to feed metal springs. This custom parts feeder was sold to an OEM that integrated it into their automated machine.

Why Vibratory Bowl Feeders?

Vibratory bowl feeders offer several key advantages for the automotive industry, including:

-

Increased Production Speed: Automotive manufacturing often involves large-scale production with high-speed requirements. Vibratory bowl feeders facilitate rapid and continuous feeding of parts, helping to maintain optimal production rates and keep pace with demanding schedules.

-

Enhanced Accuracy and Consistency: Precision is essential in automotive assembly. Vibratory bowl feeders ensure accurate and consistent placement of components, reducing errors and maintaining the integrity of complex assemblies. This precision contributes to overall product reliability and performance.

-

Versatile Handling of Components: Automotive production involves a diverse range of parts, from small fasteners and clips to larger brackets and sensors. Our vibratory bowl feeders can be customized to handle various components, adapting to the specific needs of your production line.

-

Reduced Labor Costs: Automating the feeding process with vibratory bowl feeders reduces the need for manual handling, which lowers labor costs and minimizes the risk of human error. This automation also improves workplace safety by reducing repetitive strain injuries.

-

Efficient Use of Space: Designed to fit seamlessly into existing production lines, vibratory bowl feeders optimize space utilization. Their compact design ensures that they can be integrated into tight manufacturing environments without disrupting workflow.

Ready to Get Started?

We understand the importance of quality components, competitive pricing and on-time deliveries. Our team is available to answer your questions and provide a quote for your custom parts feeding solutions.