Case Study: Vibratory Rivet Feeding System with Predefined Footprint

Feeding 4 rounded head rivets to an existing press every 3 seconds.

| Industry | Manufacturing |

| Rate | 40 PPM (20 PPM per lane) |

| Components | 2 dual-track bowl feeder systems, 2 escapements per system |

Project Overview

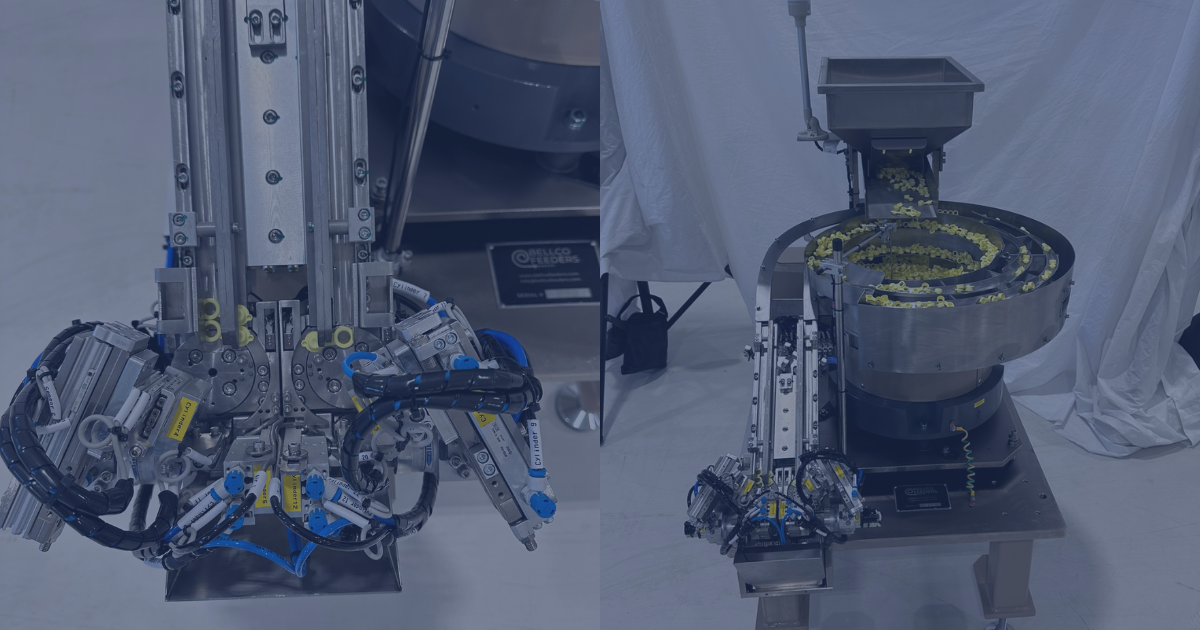

A manufacturing company came to Bellco with a complex parts feeding challenge: deliver four rounded-head rivets every three seconds, and integrate the system with their existing press. Our team engineered a dual-system multi-lane vibratory feeding solution to align seamlessly with the customer’s existing press setup, despite tight spatial constraints and demanding part geometry.

Bellco provided:

⚙️ Multi-Lane vibratory feeder system designed within specific spatial requirements

![]() Full CAD models for review and approval

Full CAD models for review and approval

🎨 Custom-painted components to match customer specifications

🎥 High-quality video of the final system for final approval and documentation

The Challenge: Feeding Rounded Rivets into a Press Bed with No Clearance

The feeding system needed to fit perfectly within a predefined footprint, align exactly with height requirements (nothing could protrude above the press bed, or it risked damage), and deliver rivets every 3 seconds.

Compounding the challenge, the rivets had rounded heads that did not allow them to sit flat. This required a custom linear track with a precise shape to keep the rivets from rocking and tilting.

The Bellco Solution: A Fully Integrated, High-Precision Feeding System

Our team collaborated closely with the customer to design a vibratory rivet feeding system consisting of:

- 2 custom vibratory bowl feeders, each with 2 tracks, mounted on either side of the existing press

- 4 escapements, (2 per system), delivering rivets every 3 seconds to exact locations on the press

- A custom-shaped linear track profile, to stabilize the rivet’s rounded head and ensure reliable orientation and movement

- A layout that adhered strictly to the press bed height restrictions, allowing seamless integration

All design work was completed in SolidWorks 3D CAD, providing the customer with full model access to review and verify integration with their existing system before manufacturing began.

Performance & Results

.png?width=1200&length=1200&name=Untitled%20(1000%20x%20563%20px).png)

Complete vibratory bowl feeder system with linear track.

Each system delivered a total of 40 parts per minute (20 PPM per lane), meeting the required production cycle time while maintaining exceptional accuracy. Escapement was tested in fully automatic mode to validate consistent part delivery and alignment with the press.

Looking for a custom parts feeding system for your application?