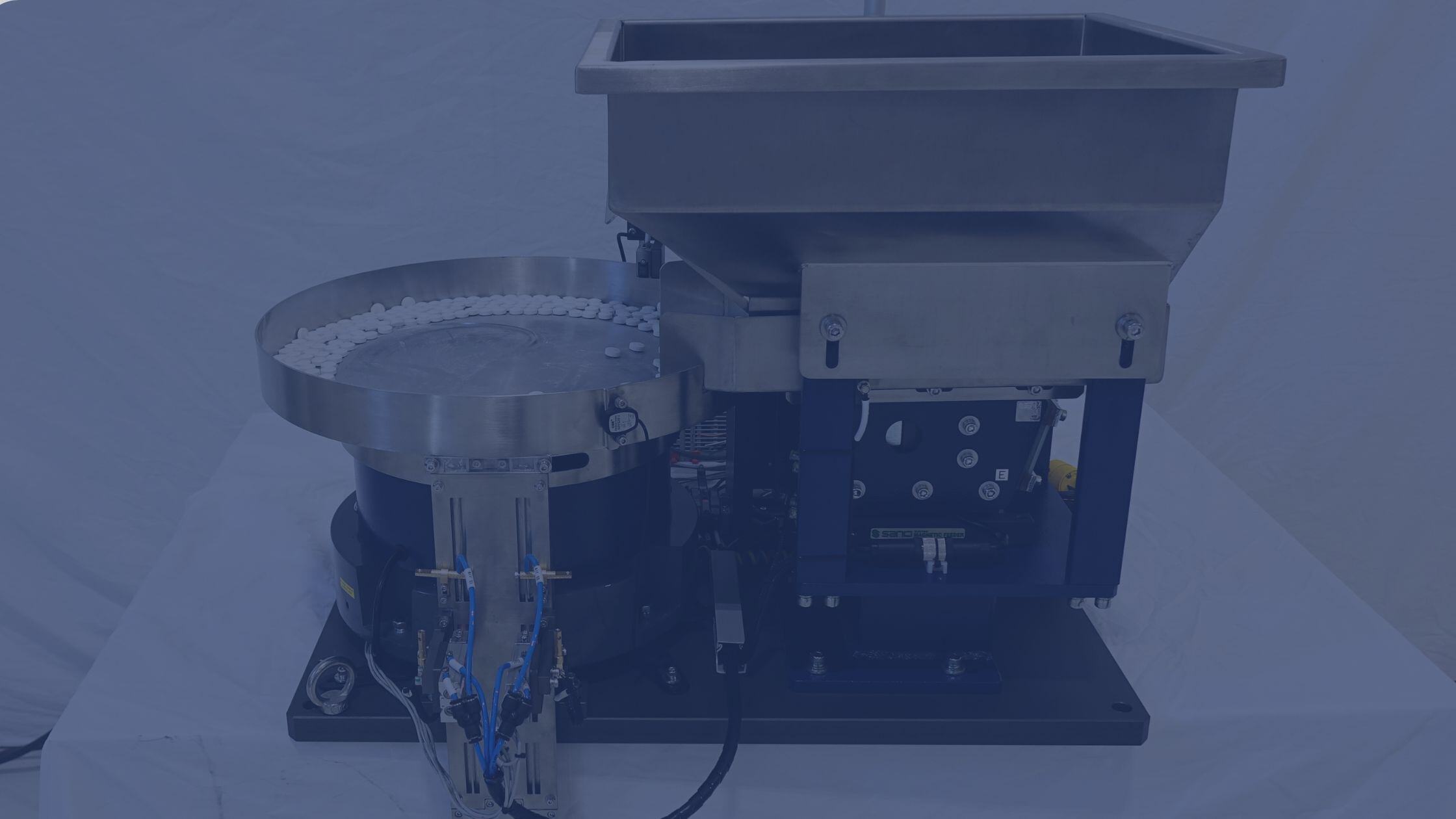

| Industry: Automotive | |

| Rate: 60 parts per minute | |

| Hopper Capacity: 30-minute unattended run time | |

| Components: Vibratory Bowl Feeder with Dual Track System, Bowl with Soft Carpet Base, and Custom Elevated Hopper |

About The Project

Bellco was approached by an industrial company seeking a space-saving and versatile parts feeding system. The client required a system capable of running two different diameter parts simultaneously within a single bowl, while maintaining high feed rates and accommodating various part lengths.

Bellco's engineering team was faced with numerous challenges during the project:

1. Space Efficiency: The client needed a solution that would optimize floor space by using one bowl instead of multiple bowls for different parts.

2. Multi-Part Compatibility: The system had to handle two different diameter parts on separate tracks, each with three different length variations, without compromising feed rates.

3. Part Protection: It was crucial to ensure that the parts were not damaged during the feeding process, requiring innovative bowl design and material selection.

4. Operator Accessibility: The client requested an elevated hopper design to enable easy loading of parts at ground level by the operator.

How our team handled emerging challenges:

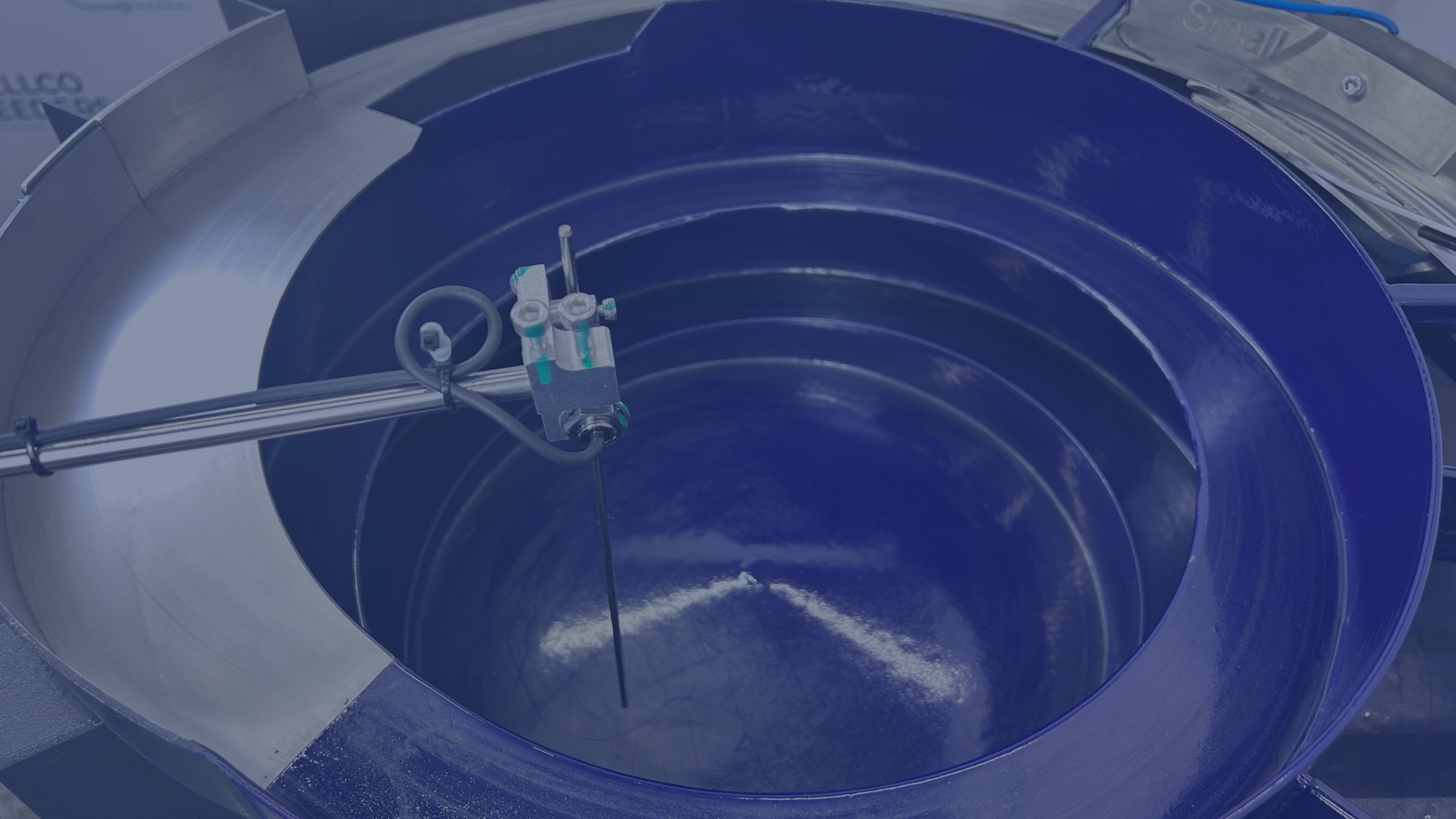

Dual Track SystemBellco's engineering team devised a dual track system that allowed the client to run two different diameter parts within the same bowl. Each track accommodated three different length variations without sacrificing feed rates. |

|

Innovative Bowl DesignTo protect the parts from damage, Bellco designed a bowl with a soft carpet base transitioning to a rubber coating along the track. This ensured gentle handling of the parts throughout the feeding process. |

|

Quick Change ToolingBellco implemented strategically placed air nozzles and a simple change tooling mechanism, enabling the client to switch between tracks rapidly, within seconds, for seamless production transitions. |

|

Elevated Hopper with HopperBellco engineered an elevated hopper that allowed the operator to load parts from ground height conveniently. A level sensor installed in the bowl communicated with the hopper, triggering it to load more parts as needed, ensuring uninterrupted operation and maximum efficiency. |

|

Space SavingsBy utilizing one bowl for multiple parts, the client achieved significant space savings in their production facility. |

Results

Bellco's innovative parts feeding solution not only met the client's specific requirements but also delivered tangible benefits in terms of efficiency, space utilization, part protection, and operator convenience.

In summary, Bellco Feeders' advanced vibratory bowl feeder system offers manufacturers significant operational advantages. The dual track system and innovative bowl design improve flexibility and protect part quality, while quick change tooling and the elevated hopper enhance efficiency and ease of use. Additionally, space savings from consolidating parts handling into a single feeder optimize production facility layout. Together, these benefits lead to increased productivity, reduced downtime, and a more streamlined and efficient manufacturing process.