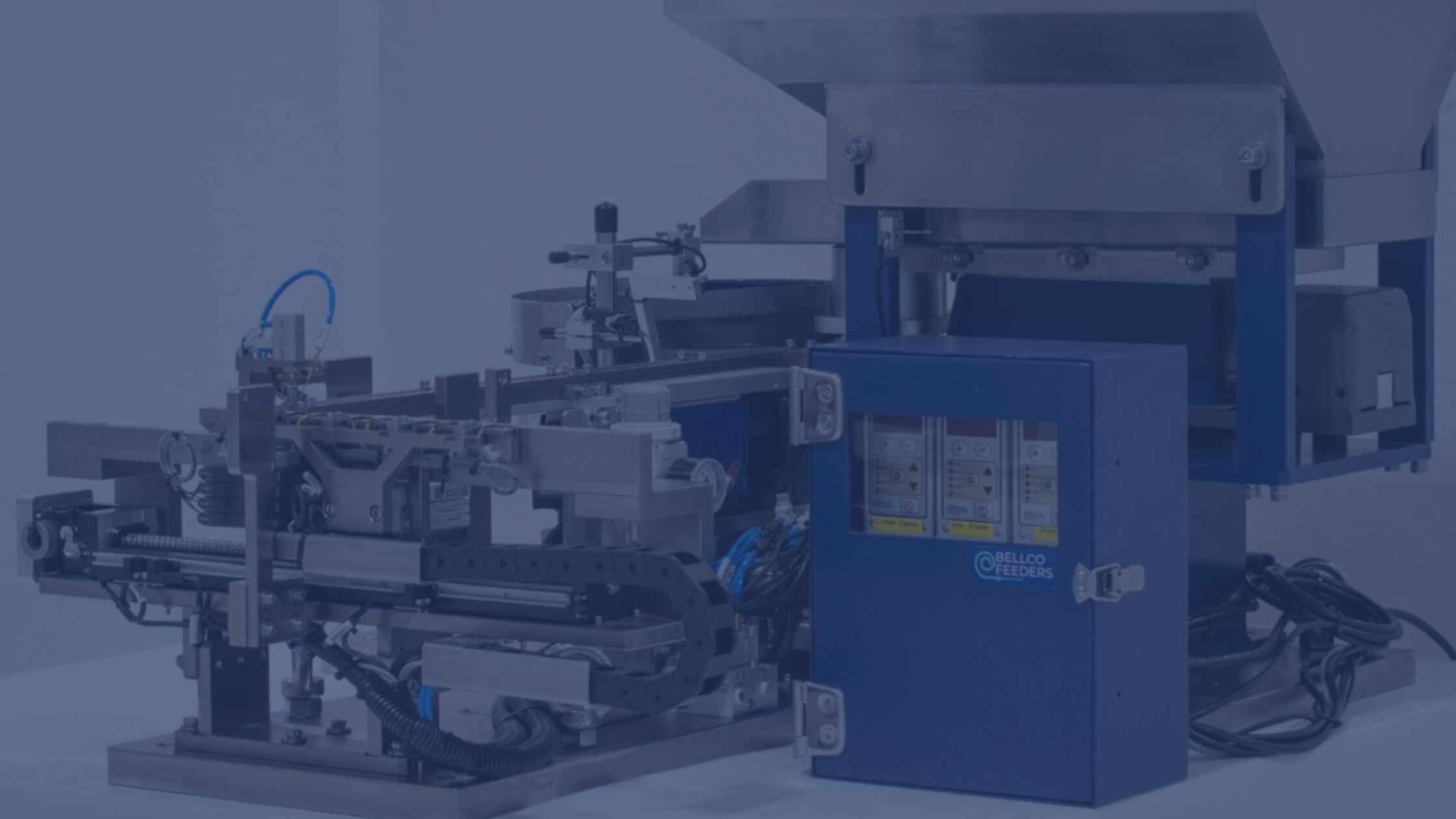

From Concept to Production: Bellco's Approach to Custom Feeding Systems

Engineering Solutions for Precision Manufacturing

When you're tasked with integrating a custom parts feeding system, the stakes are high. Precision, speed, footprint, and compliance all have to align perfectly. In this article, we walk you through the proven process we follow at Bellco to move from concept to full production-ready feeding systems.

Step 1: Defining Your Feeding Requirements for Maximum Success

Every project starts with a deep dive into the client’s production needs. Whether you're in pharmaceuticals needing FDA-compliant stainless steel, or automotive manufacturing looking to streamline automation, we collaborate closely to define key parameters up front and set the foundation for success.

Key factors we consider:

- Target production rates and cycle times

- Part orientation and handling needs (small, delicate, or oddly shaped parts)

- Space constraints within your facility

- Regulatory or cleanliness standards

We offer a complete range of parts feeding solutions tailored to your specific application:

- Vibratory Bowl Feeders: Our most adaptable option, optimized for high-volume production with small to medium components.

- Step Feeders: Engineered for applications requiring gentle component handling or reduced noise levels.

- Bulk Part Hoppers: Precision-designed to control component delivery to robotic systems or assembly stations.

For many systems, an integrated approach combining multiple technologies provides the best result.

Step 2: Your Feeding System Is Designed for Reliability and Efficiency

With requirements defined, our engineering team begins designing a fully customized system. Using SolidWorks 3D CAD software, your feeding system is modeled to exact specifications, ensuring seamless integration with your existing production environment. This virtual design phase allows you to:

- Visualize the full system layout

- Identify potential bottlenecks early

- Approve the design before any manufacturing starts

Step 3: Turning Your Approved Design into a Production-Ready System

With designs approved and finalized, it’s time to bring the concept to reality.

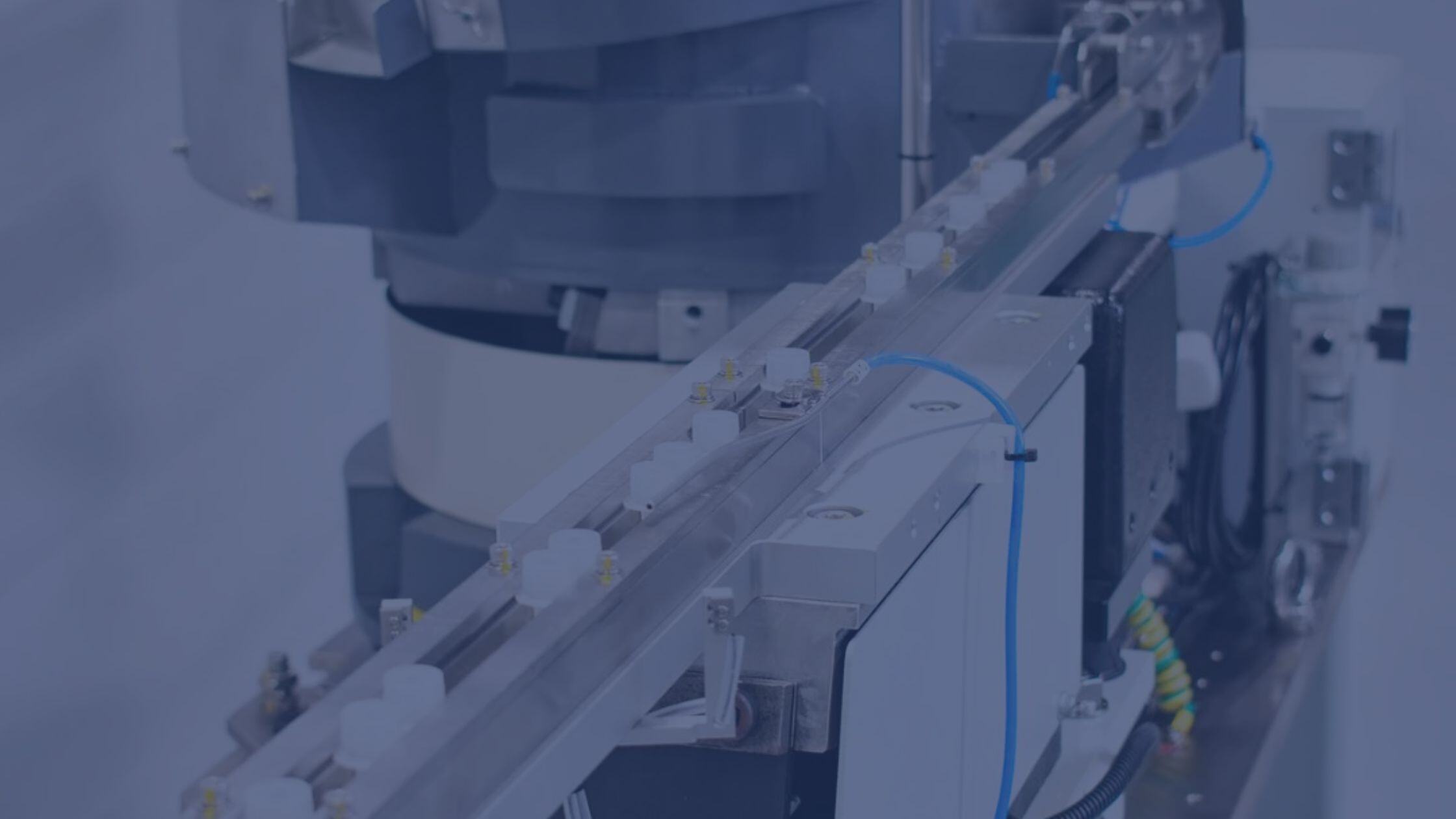

Step 4: How We Ensure Your System Performs Before It Reaches Your Floor

Before shipment, every feeding system undergoes a full test run in our facility to validate performance. This includes:

- Speed & efficiency testing at full production rates

- Part orientation & escapement accuracy

- Durability assessments under simulated production conditions

For clients who can’t visit in person, we offer live video run-offs, providing real-time visibility into system performance before approval and shipment.

Step 5: What Happens After Installation: Support You Can Count On

Typically, delivery occurs within 10–12 weeks from order to installation. But your relationship with Bellco doesn't end there. We offer ongoing support, including:

- Spare parts availability

- 1–year warranty

- A dedicated service team

Real-World Success: See It in Action

Facing a challenging part feeding application? Learn how companies like yours have improved production efficiency, reduced downtime, and increased throughput with custom Bellco systems.

Let's Talk About Your Feeding System Needs

Bellco is more than a manufacturer. We’re a strategic partner in precision automation. Our expertise helps clients increase production rates, reduce downtime, and improve efficiency.

If you're facing a challenging part feeding application, we invite you to experience the Bellco difference. Contact us to discuss how we can help with feeding systems that deliver real performance improvements.

FAQ

How long does it typically take to develop a custom feeding solution from initial consultation to installation?

Our typical delivery is 10-12 weeks from the time of order to the time the system is in your facility.

What industries do you serve?

We design and build parts feeding systems for nearly every industry, including medical and pharmaceutical, automotive, consumer products, appliances, electrical components, aerospace and more.

What types of maintenance are required for your feeding systems, and how frequently?

Our feeding systems are designed to last but, as with any automated system they require routine maintenance and tune-ups and replacing wear components. We stock common wear components that are available for quick shipment to you. Our team of service technicians are also available to assist either remotely or travel on-site.

How do you test systems before delivery to ensure they'll perform as expected?

Our team ensures quality through complete run-off testing. Before every product ships, a production video is sent to each client for acceptance, leaving ample time for de-bug and any modifications needed to ensure each product is meeting the rate and quality requirements that our clients expect.