The Emphasis On Sustainability, And More Importantly Sustainable Manufacturing, Continues To Grow. The Challenge For Most Manufacturers Is Deciding On Where To Start, Or How To Take Their Current Sustainability Operations To The Next Level.

What Is Sustainable Manufacturing?

As listed on the EPA website, sustainable manufacturing is the creation of manufactured products through economically sound processes that minimize negative environmental impacts while conserving energy and natural resources. In other words, manufacturers who make sure they are producing their products in the best way possible, for their employees, their customers, and our environment.

The Importance Of Sustainably In Manufacturing.

A recent study showed that manufacturers consume nearly a third of the energy in the United States; couple that with an ever-growing emphasis on sustainability and the need for “smarter” manufacturing practices takes center stage.

The challenge for most manufacturers is deciding on where to start, or how to take their current sustainability operations to the next level.

Five Ways To Start Or Continue The Journey Towards Sustainability:

1. Engage Employees

The Conference Board® Global Consumer Confidence Survey, conducted in collaboration with Nielsen Q2 2018, showed that 81% of global respondents said that it is “extremely” or “very” important that companies implement programs to improve the environment. Engaging employees throughout the company in sustainable initiative can improve corporate culture, create value, and improve business operations.

2. Reduce Scrap Materials And Waste

In manufacturing it can be difficult, if not nearly impossible, to use 100% of materials but, when evaluating sustainable manufacturing the goal should always be to produce the same quality components, using the least amount of energy and resources possible.

Re-evaluate whether the choice of investing in more accurate or automatic manufacturing equipment, it may introduce opportunities for waste reduction and offer a quicker ROI than originally anticipated.

3. Conduct An Energy Audit

Take some time, possibly dedicate a team, to define the types of energy your facility uses and how much. Then, put together a quick action plan on how to reduce that energy. The key here is to start small and grow from there. For example, add motion sensors to the lights in rooms that don’t have continuous occupancy or, turn off equipment that is idling and does not need to be powered on.

4. Recycle Or Repurpose

Look at the manufacturing processes that produced the most waste and evaluate if any of that waste can be recycled or repurposed. Determine the best way to categorize recyclable or reusable materials and make it simple for everyone to participate. Separating materials and including education and signage can improve engagement and recycling rates.

5. Leverage The EPA’s E3 Program

The United States Environmental Protection Agency (EPA) has pioneered a federal program to help communities, manufacturers and manufacturing supply chains improve sustainability and continue to navigate today’s ever-changing economy.

The program , E3 stands for Economy, Energy and Environment – the three most important factors to consider when planning for a sustainable future. They have a whole library of useful resources and sustainability tools. https://www.epa.gov/e3/e3-sustainability-tools

Bellco Feeders + Sustainability

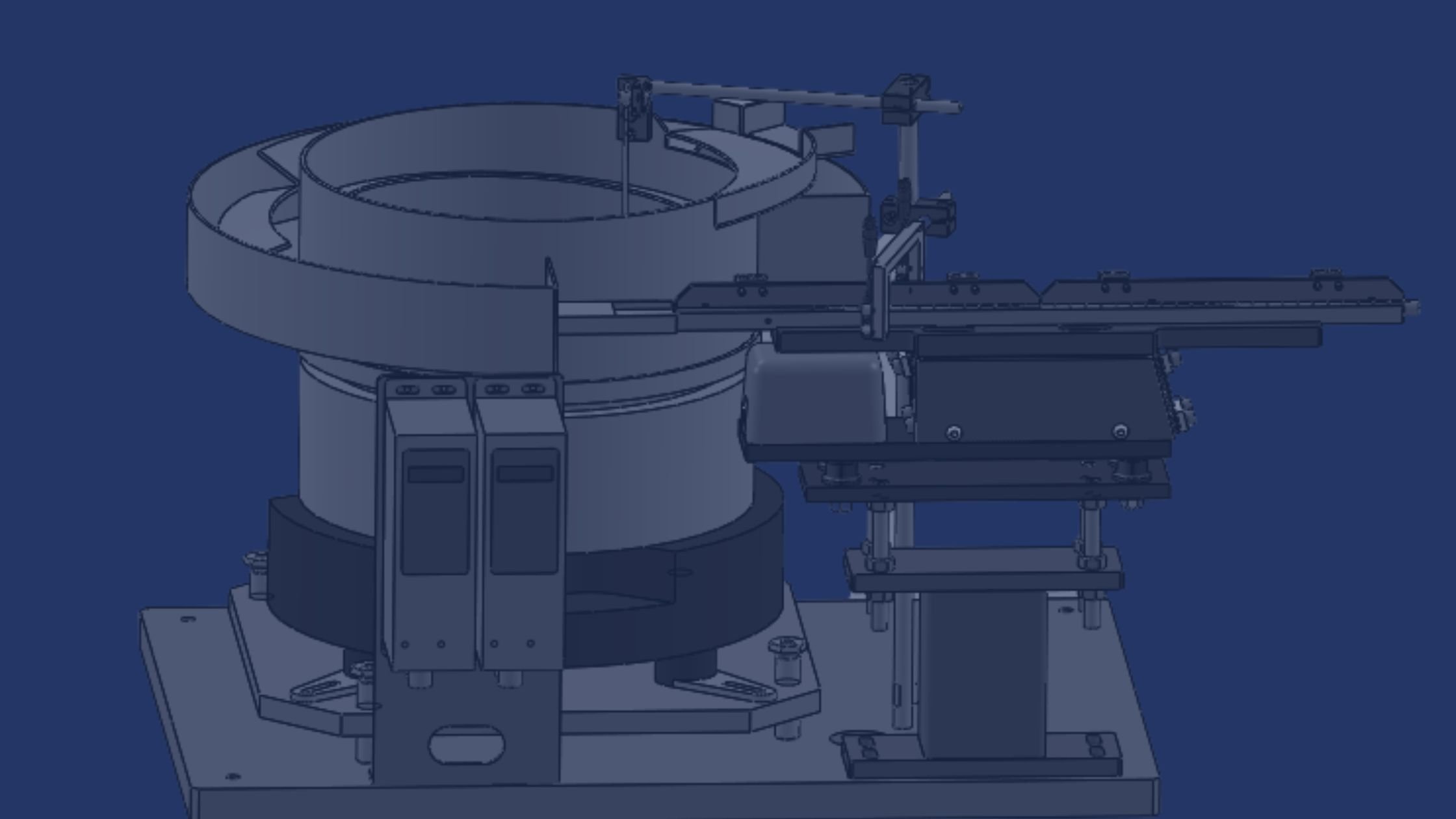

We recognize the need for sustainable manufacturing, so we design our feeders and have made an emphasis to conduct our business with sustainability in mind. All our bowls are designed with sophisticated controls that efficiently use electricity to create vibrations only when needed to move parts. When the bowl is not actively running, it’s idling to conserve energy. Our engineers also create bowl feeder and track designs that move parts in the most efficient way, reducing the frequency the bowl needs to turn on.