Automation in Manufacturing: How Parts Feeding Systems Can Help Get the US Ready for Industry 4.0

Automation in manufacturing is an ever-evolving process. From aerospace to automotive, traditional parts feeding systems are being replaced by more efficient automation solutions. Automated parts feeding systems can reduce the need for manual labor, improve the accuracy and speed of assembly, and help increase productivity. In addition to promoting a workplace that is more safe than traditional manual assembly and manufacturing methods.

In this article, we'll discuss why automated parts feeding systems are the future of manufacturing and how they can help make the US ready for Industry 4.0.

Overview of The Fourth Industrial Revolution, 4IR, or Industry 4.0

The Fourth Industrial Revolution, or Industry 4.0, represents the convergence of physical, digital, and biological technologies that is transforming manufacturing.

At its core, Industry 4.0 is about using technology to increase efficiency and productivity in manufacturing. This can be done through automating processes and using data to make better decisions.

One area where Industry 4.0 is having a big impact is in parts feeding systems. By automating the process of feeding components to machines, manufacturers can improve efficiency and reduce costs.

Parts feeders are used in a variety of industries, from automotive to consumer electronics. In the automotive industry, they are used to feed parts to assembly lines. In consumer electronics, they are used in the manufacture of smartphones and other devices.

There are several different types of parts feeders, each with its own advantages and disadvantages.

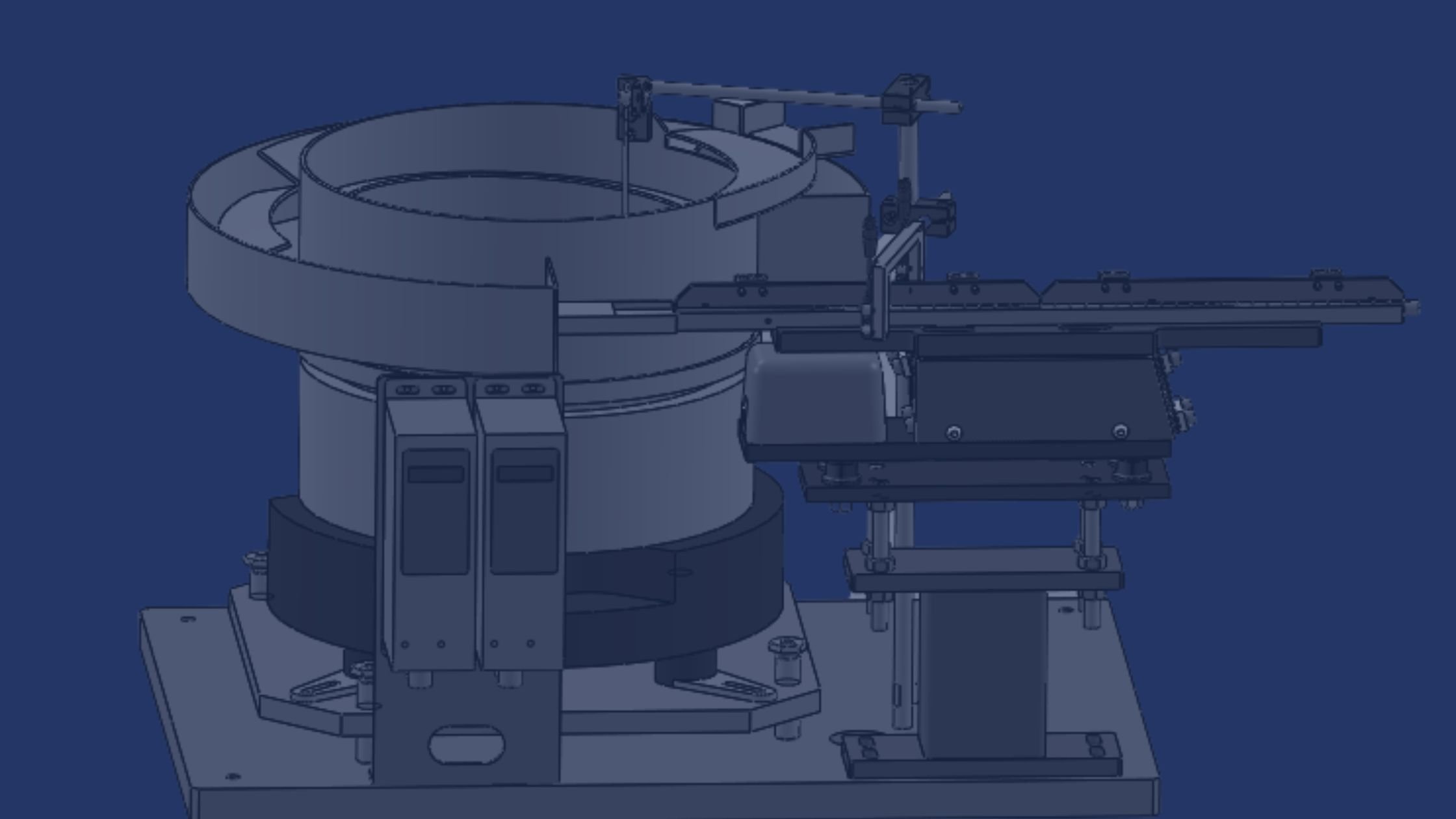

- Vibratory bowl feeders, use vibration and custom tooling to move parts through a series of rotary tracks to orient parts from bulk into the correct position for assembly

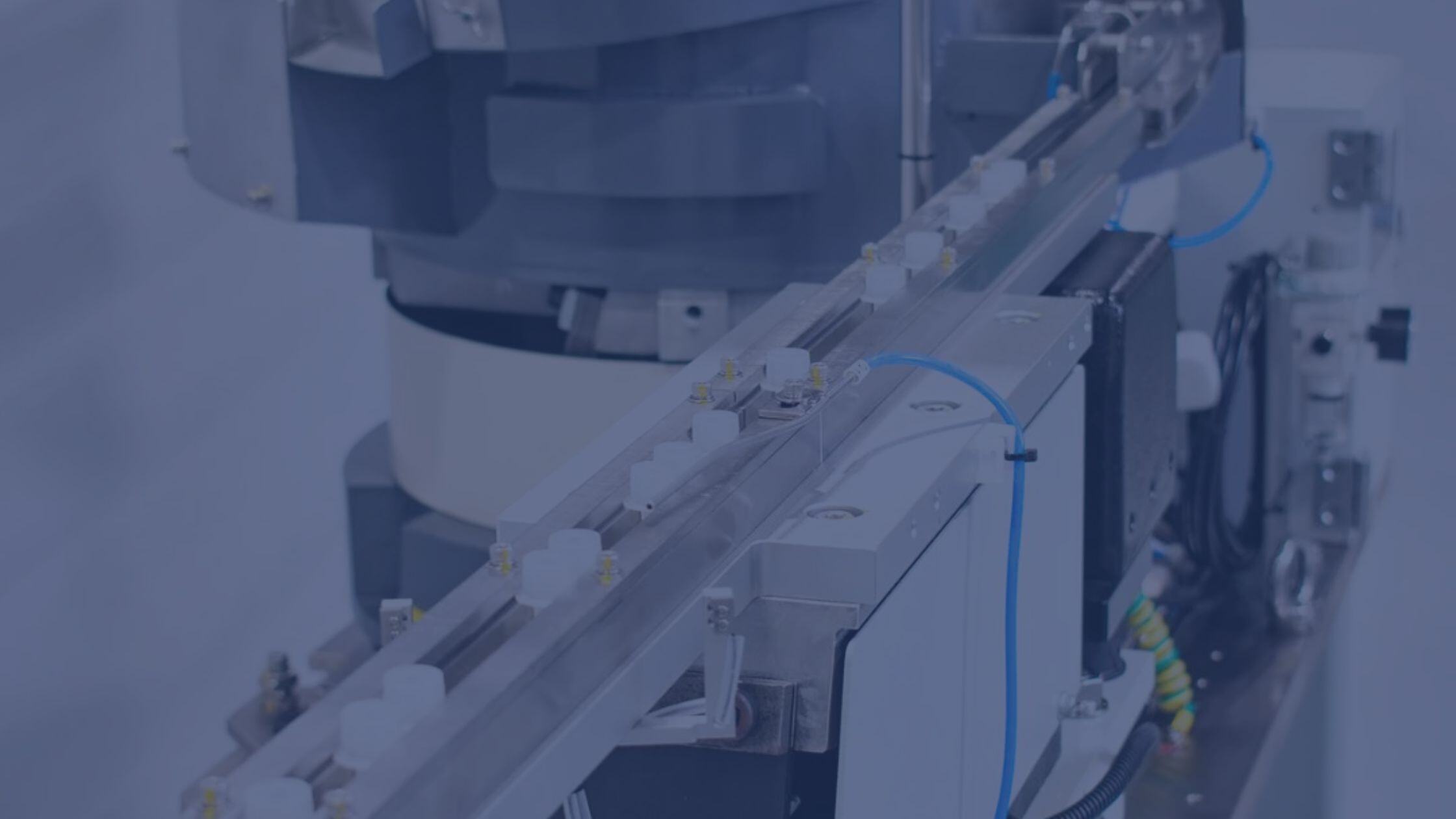

- Linear track systems, use a series of linked tracks to move parts from one station to another, typically using air guidance or vibrations to move the parts forward

- Belt-driven conveyor systems, use a belt to move parts from one station to another.

- Flex feeders, are often integrated with vision based robotic solutions that have the ability to take images of parts on a flat surface and pick them up regardless of their orientation.

Parts feeders are just one of the many technologies that have been developed in response to Industry 4.0. Other solutions include automation, 3D printing and digital twins. All these solutions offer manufacturers the chance to improve their efficiency and reduce costs.

By taking advantage of the Fourth Industrial Revolution, manufacturers can realize greater gains in productivity and performance. This will enable them to become more competitive and create better products for consumers.

The Future of Manufacturing in the United States

The United States has long been a world leader in manufacturing, but in recent years, other countries have been catching up, and automation is a big part of that. Automation in manufacturing allows for greater efficiency and productivity, and it's something that the US will need to embrace if it wants to stay ahead of the curve. For this reason, the implementation of automation throughout US manufacturing facilities is paramount to the industries long-term success.

Investing in automation and innovation will allow the US to remain competitive against some manufacturing facilities in lower-cost countries. Further dicing into research and development, developing new and better technologies, as well as exploring areas such as 3D printing and robotics are all important steps forward in this direction – provided they’re backed with adequate government support.

How Parts Feeding Systems are Evolving

To stay competitive, many manufacturers are turning to automation to increase productivity and efficiency. Parts feeding systems are an essential part of many automated assembly lines. These systems have evolved significantly over the years and continue to do so as technology advances.

The most basic parts feeding systems simply sort and orient Pieces so that they can be fed into a machine for further processing. However, more advanced systems can handle multiple pieces at once and can even use robotic arms or other machines to place the pieces where they need to go.

One of the biggest challenges facing manufacturers today is keeping up with the demand for new products. To meet this challenge, manufacturers need to be able to rapidly prototype new products and quickly changeover their production line to accommodate new models. Flexible parts feeding systems are key to this process as they can easily be reconfigured to handle different types and sizes of pieces.

Another trend that is impacting parts feeding systems is the shift towards miniaturization. As electronics and other components get smaller, so too do the pieces that need to be fed into assembly machines. This presents a challenge for parts feeding systems as they need to be able to accurately handle very small pieces without damaging them. In some cases, specialized cameras or other sensors are used in conjunction with robots to achieve this level of accuracy.

Conclusion

As industrial automation continues to gain traction across the United States, it's evident that parts feeding systems can be a key component in helping businesses become ready for Industry 4.0. Through advanced robotic technologies like artificial intelligence and machine learning, these systems can identify and sort materials quickly and accurately without sacrificing on quality or speed. By automating tedious tasks associated with the production process, parts feeding systems enable American businesses to push through any productivity plateau they craft might have experienced before putting them on the fast track towards achieving their digital transformation goals.

About Bellco Feeders

As one of the highest-quality parts feeding companies in the US market, Bellco Feeders has years of experience of helping manufacturers automate their parts feeding processes a wide variety of applications. Our feeders can handle a variety of small to medium sized parts and can be designed to meet the specific needs of your application. In addition to our standard product line, we also offer custom-engineered solutions to meet the most challenging assembly requirements.

Bellco Feeders is your go-to source for high-quality and low-cost vibratory bowl feeders, step feeders, flex feeders and custom conveyor systems. Our team of experts will work with you to understand your unique application and design a system that will streamline your assembly process and improve your bottom line.