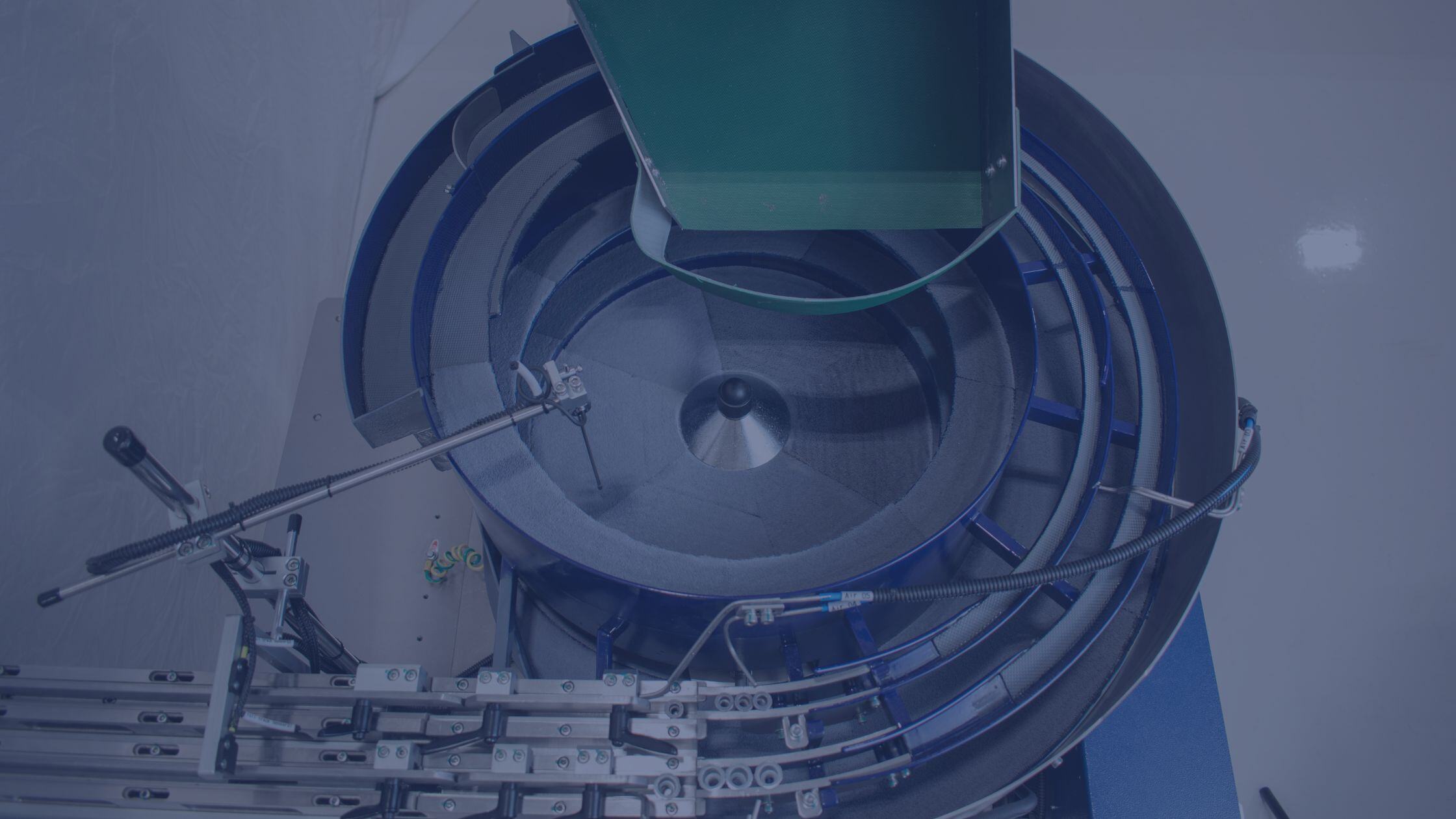

At Bellco, we design and manufacture small, automated parts-feeding systems, which include vibratory bowl feeders, step feeders, flex feeders, and conveyor systems. Our systems are engineered using the latest automated technology and are designed to integrate with robotic and AI packages to provide a complete solution and a more efficient manufacturing experience. Over the past many years, we’ve worked to optimize our internal processes and keep our manufacturing costs low, so we can offer high-quality and robust parts-feeding solutions to Machine Builders and Integrators who can pair our technology with robotic arms and AI, creating a turn-key solution for manufacturers.

The Future of Parts Feeding: Innovations in Robotics and AI

Part-feeding is a crucial element of many manufacturing operations, ensuring that the correct components are in the right place at the right time for assembly or processing. Traditional manufacturing processes relied on manual part-feeding, which was time-consuming, error-prone, and limited in terms of production speed and efficiency.

Part-feeding is a crucial element of many manufacturing operations, ensuring that the correct components are in the right place at the right time for assembly or processing. Traditional manufacturing processes relied on manual part-feeding, which was time-consuming, error-prone, and limited in terms of production speed and efficiency.

Today, material handling is highly automated, faster, more precise, and safer, thanks to advancements in robotics and AI. These innovations optimize parts flow, identify and resolve problems in real time, and handle parts more safely and efficiently. Automated part-feeding systems, such as vibratory bowl feeders, flex feeders, and conveyor systems, are cost-effective solutions that cater to parts of various sizes and geometries. By reducing the risk of human error, these systems enhance productivity and improve the accuracy and consistency of production processes across diverse manufacturing environments.

Integrating robotics and AI with part-feeding systems paves the way for smart factories that streamline operations and boost competitiveness. Combining parts-feeding systems with robotic technology creates a fully automated production line capable of operating 24/7 with minimal human intervention. AI assists in predicting when parts need replenishing, detecting and rectifying errors in the feeding process, and adjusting the speed and rate of feeding to match the production line's requirements.

In this article, we explore the role of part-feeding in manufacturing processes and the impact of robotics and AI on its efficiency. You'll discover the benefits of incorporating robotics and AI into your part-feeding systems, such as increased speed, efficiency, accuracy, and safety, making it a key area of manufacturing innovation. We will also discuss the potential drawbacks and help you make informed business decisions on which Industry 4.0 technologies to implement in your application.

Robotics in Part Feeding

Machine automation has emerged as a powerful tool in the field of part-feeding, providing further opportunities for you as a manufacturer to stay on top of your competition. Incorporating robotic technology can be a valuable asset to the part-feeding process and has enabled you to increase your speed, accuracy, performance, and safety during production. Our customers have used robotics in the following ways:

- To pick parts from a custom parts escapement

- To pick parts directly from a vibratory in-line track

- Directly from our Flex Feeding systems

- To pick parts that are fed onto a conveyor system

Using robotic arms with parts feeders can accurately and efficiently feed parts into a wide variety of manufacturing application. These systems typically use robotic arms or manipulators with grippers, suction cups, or other end-effectors to pick up and position parts. With robotics, you can improve on many common human errors commonly associated with manual processes, such as misaligned parts or missed feeds.

At Bellco Feeders we design the most suitable automated part-feeding system for you and advise you on robotics and AI systems you can integrate into your manufacturing application.

Here are examples of some technologies in the robotics field you can pair with your parts-feeding system:

- Industrial Vision systems serve as essential elements in both robotics and AI. They frequently work in tandem with robotic part-feeding systems to direct their operations. The vision system interprets visual data to manage the movements of a robotic arm or manipulator, signifying its vital role within the robotic system. This function enables enhanced interaction with the environment and allows for more precise and efficient task execution.

- Collaborative Robots, also known as cobots, perform specific tasks, such as feeding parts into the manufacturing process, freeing human workers to focus on higher-level tasks. They reduce the risk of injury by working in tight spaces and carrying out intricate movements with precision and accuracy. Unlike traditional industrial robots, cobots are user-friendly and you can program them with ease. Thanks to their intuitive interfaces and plug-and-play capabilities, you don't need extensive training or expertise to incorporate cobots into your production processes quickly. Moreover, cobots are highly adaptable and capable of learning and adjusting to shifting manufacturing environments. You can use cobots to handle small batch sizes and frequent product changes, enabling them to react rapidly to market demands and stay competitive. By working alongside humans, cobots offer a versatile and cost-effective solution to many manufacturing problems.

- Autonomous Mobile Robots transport parts to and from the feeder, which allows you to reduce the number of manual tasks. Operating independently, these robots can quickly and freely move within the manufacturing plant and deliver parts to the feeder in an efficient manner. AMRs adapt to different manufacturing environments while offering flexibility and cost-effectiveness as they navigate complex layouts and tight spaces, and can work collaboratively with human workers. They can adjust their routes without infrastructure changes.

AI in Part Feeding

Artificial intelligence has an increasingly important role in part-feeding system design and operation. It is a valuable asset to part-feeding systems’ robotization and it optimizes the part-feeding process to be more efficient and precise.

Here are some of the innovations in AI that can be integrated into part-feeding systems:

- In the AI aspect, Vision Systems use advanced algorithms to analyze and interpret captured images. You can use vision systems to identify and sort parts and perform quality control tasks like inspecting for defects or ensuring proper assembly. They can quickly and accurately identify and categorize the components based on unique visual features like size, shape, color, texture, or other characteristics. These systems continuously improve their accuracy and reliability using deep learning algorithms.

- Predictive Maintenance Systems optimize feeder performance and reduce downtime via machine learning algorithms. For example, they can monitor the performance of feeder motors and predict when they are likely to fail, allowing you to schedule maintenance before the feeder stops working. In the case of feeder systems, predictive maintenance systems monitor the feeder motors and other key components, collecting data on vibration, temperature, and power consumption to detect any deviations from expected performance. Based on this analysis, the system predicts when a component is likely to fail and alerts maintenance personnel to schedule maintenance before a failure occurs. These systems can lead to increased productivity and cost savings, as well as improved quality control by catching potential issues before they cause defects in production. Moreover, predictive maintenance systems use the collected data to optimize the feeder performance over time, identifying opportunities to improve efficiency or reduce waste and allowing you to improve your operations consistently.

- Real-Time Monitoring Systems detect defects or jams in the feeder. These systems can quickly identify and resolve issues, reducing the risk of downtime and keeping the feeder running smoothly. They can alert operators to clear the jam before it leads to further preventing damage to the feeder and other equipment, as well as reduce the risk of defects or quality issues in the final product. Smart Feeder Controls adjust and optimize feeding speeds, patterns, and intervals based on real-time data, to improve the efficiency and accuracy of part-feeding and reduce the chances of congestion. They ensure a smooth flow of parts with the correct orientation and position, reducing the risk of production disruptions and improving efficiency.

Our Vision for the Future

Automation amplifies part-feeding by offering you new solutions to boost speed, accuracy, performance, and safety during production. Robotics, especially robotic feeders, cobots, and AMRs, have become valuable assets in the part-feeding process as they automate manual tasks and eliminate common human errors.

AI technologies, such as vision systems, predictive maintenance systems, real-time monitoring systems, and smart feeder controls, show immense potential for improving efficiency, accuracy, and safety in part-feeding systems. As technology progresses, we expect the emergence of even more advanced and effective AI solutions that will boost part-feeding system efficiency, making a significant impact on the future of manufacturing.

At Bellco Feeders, we design and manufacture small automated parts-feeding systems. With more than 20 years of experience, our engineers continuously research the market and expect and work on the development of more sophisticated industrial feeders capable of handling complex tasks with better speed and precision. Bellco Feeders remains dedicated to staying ahead of these advancements by providing high-quality, robust parts-feeding solutions to Machine Builders and Integrators. You can then integrate our technology with robotic arms and AI, creating comprehensive manufacturing solutions. We firmly believe that incorporating robotics and AI into part-feeding systems will remain a game-changer for you who are striving to stay competitive and meet the ever-changing market demands.

Implementing Robotics and AI Technologies: A Step-by-Step Guide

To research whether and how to implement robotics and AI, also known as Industry 4.0 technologies, in your manufacturing process, you can follow these steps:

- Familiarize yourself with the Industry 4.0 concept: You should understand the benefits and potential drawbacks of implementing Industry 4.0 technologies in your manufacturing process.

- Identify pain points in your current manufacturing process: You should analyze your production data, conduct surveys or focus groups, or consult with subject matter experts to identify the pain points or bottlenecks in your current manufacturing process.

- Research available Industry 4.0 technologies: You should research the available Industry 4.0 technologies that could potentially address these pain points by consulting with vendors, attending conferences or trade shows, or conducting your research online.

- Create a list of potential vendors or partners: Begin by searching online, asking for recommendations from colleagues in the industry, or attending relevant events to find vendors or partners experienced in implementing robotics and AI technologies in manufacturing processes.

- Evaluate their background and skills: Assess each potential vendor or partner based on their experience, understanding of the industry, and success in implementing similar projects. Examine case studies, client feedback, and any applicable certifications to determine their ability to fulfill your specific requirements.

- Ask for proposals and estimates: Reach out to the selected vendors or partners and request comprehensive proposals and cost estimates for your project. Ensure they include details on the scope of work, implementation schedule, budget, and any extra services they provide, such as training, support, and maintenance.

- Verify references: Contact the previous clients of the vendor or partner to gather information on their performance, responsiveness, and overall satisfaction with the services delivered. This feedback will help you make a well-informed decision about the best vendor or partner for your project.

- Determine their fit with your company culture: Smooth collaboration between your team and the vendor or partner is crucial for successful implementation. Evaluate their communication style, work ethic, and adaptability to see if they are compatible with your company's culture and values.

- Evaluate potential solutions that can address your pain points by comparing the costs and benefits of each solution, as well as any potential risks or challenges associated with implementing the technology.

- Assess ongoing support and services: Familiarize yourself with the post-implementation services provided by the vendors or partners, such as training, updates, maintenance, and technical assistance. Opt for a vendor or partner who can offer consistent and dependable support throughout the technology's lifecycle.

- Create an implementation plan that includes a timeline, budget, and training employees on the new technology.

- Implement the technology according to your plan and closely monitor the results, making any necessary adjustments to ensure the technology meets your goals and objectives.

When researching and implementing Industry 4.0 technologies, it is important to have a clear understanding of your pain points and objectives and the willingness to devote the time and resources required to evaluate and implement potential solutions.

Conclusion

In conclusion, the integration of robotics and AI technologies has the potential to revolutionize part-feeding systems, significantly enhancing speed, accuracy, and safety in manufacturing processes. The combination of robotic feeders, cobots, and AMRs, alongside advanced AI solutions like vision systems and predictive maintenance systems, can lead to substantial improvements in efficiency, quality control, and overall productivity.

However, it is essential to carefully consider the potential challenges associated with implementing these technologies, such as costs, workforce impact, and safety concerns. By taking a balanced approach and finding ways to mitigate these challenges, you can unlock the full potential of robotics and AI in part-feeding systems and stay competitive in an ever-evolving market.

At Bellco Feeders, we are committed to staying at the forefront of these advancements, offering high-quality, reliable, and robust parts-feeding solutions tailored to your manufacturing needs. We encourage you to explore how our expertise in designing and manufacturing automated parts-feeding systems, which can be paired with robotic arms and AI technologies, can create a turn-key solution that enhances your operations and helps you maintain a competitive edge in the industry.

Reach out to us today to discover the advantages of partnering with Bellco Feeders for your next manufacturing project.