Case Study: Feeding Flexible Packets for High-Speed Packaging Lines

Packet Feeder System for Flimsy Packaged Goods

| Industry | Packaging |

| Rate | 80 PPM |

| Components |

|

Project Overview

A packaging company came to Bellco with the challenge of feeding thin, flexible packets onto a conveyor without overlap or jamming. These packets often stick together or stack, which will disrupt downstream processes.

The customer needed a single-file flow of packets, spaced apart, at 80 parts per minute. Any contact between parts could cause jams or errors in packaging.

Our team provided a custom feeding system that included:

- A vibratory feeder bowl designed for the packet geometry

- An exit conveyor to maintain part separation

- A 4.5 cu. ft. elevated conveyor hopper to support continuous part flow

A 3D CAD file of the system, designed in SolidWorks, was approved by the customer before build.

.png?width=1200&length=1200&name=Bowl%20&%20Conveyer%20Above%20(Best).png)

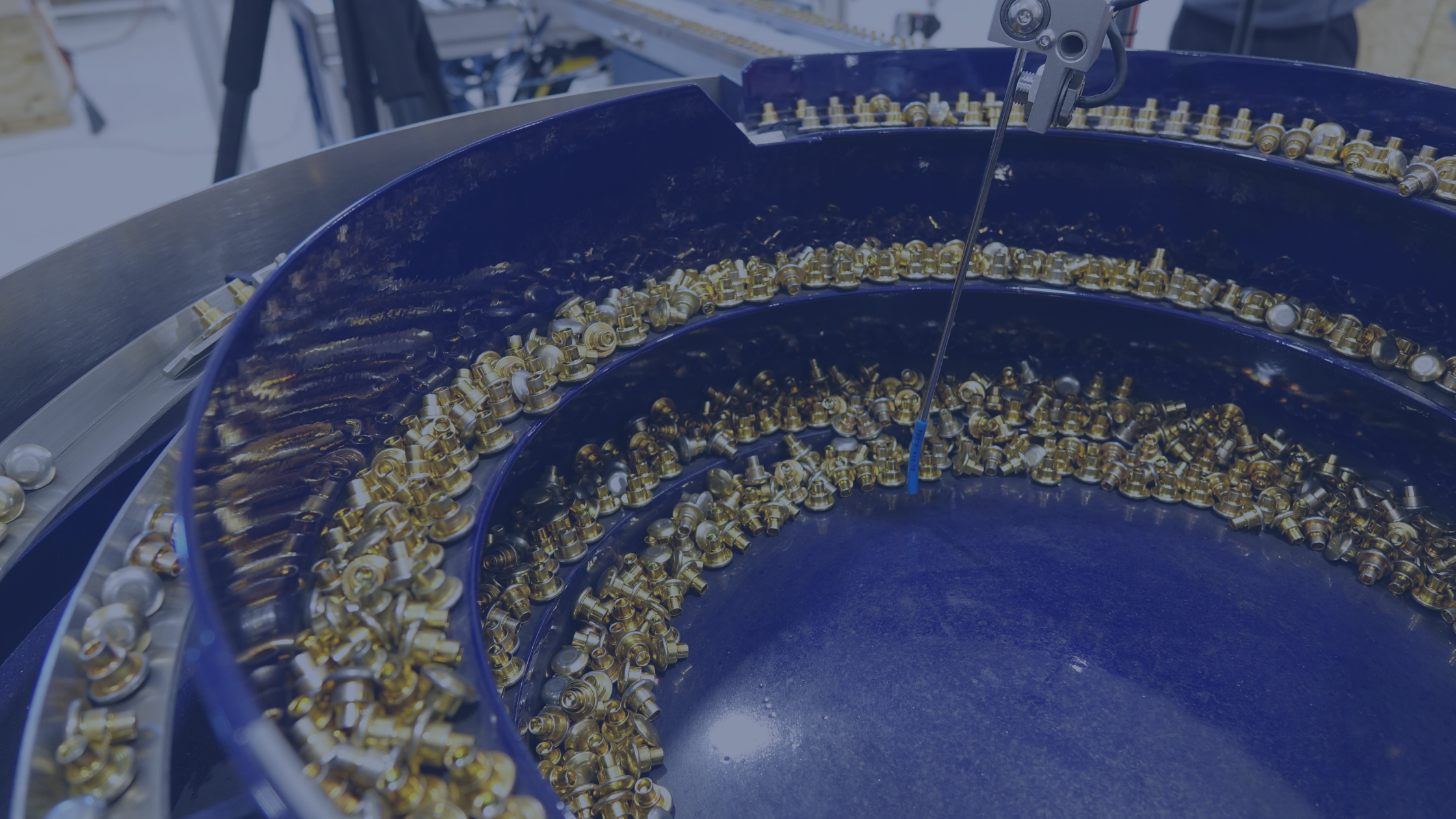

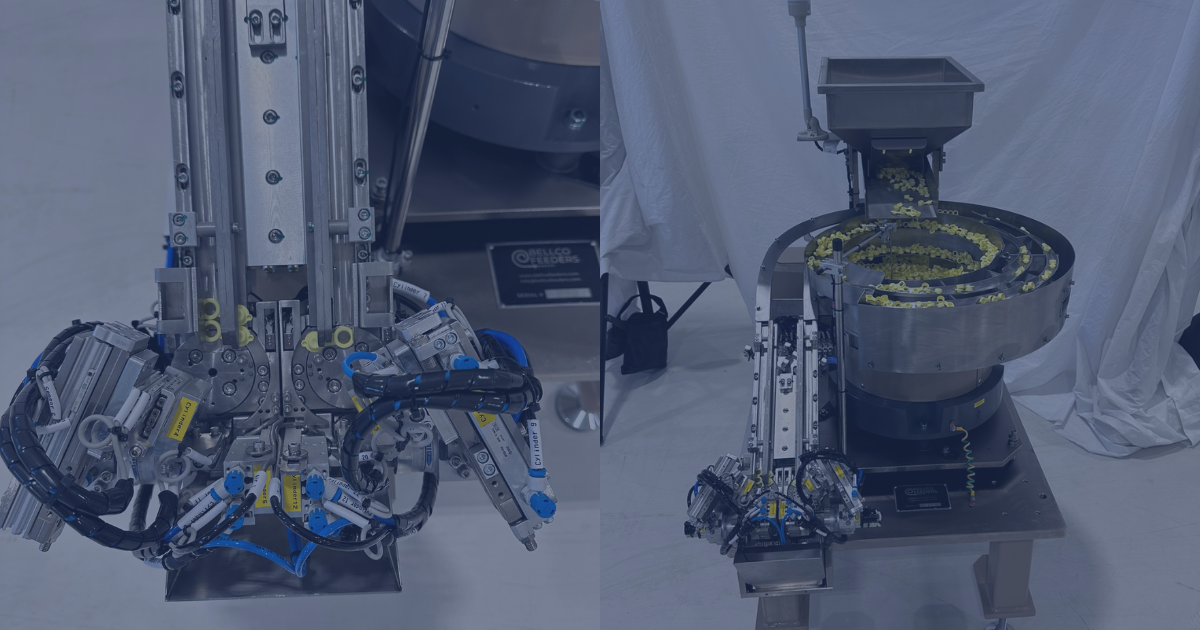

Vibratory bowl feeder filled with flexible packets.

View of vibratory bowl feeder leading into exit conveyor.

The Challenge

Flimsy packets tend to overlap or double-stack when conveyed. This customer required clean separation between packets. Most off-the-shelf systems couldn’t meet that requirement without manual sorting or custom intervention.

The Bellco Solution

Our team engineered a custom feeding solution tailored to the application. The feeder bowl was tuned for the part’s specific material and size. An exit conveyor created spacing as parts transitioned out of the bowl. The elevated hopper provided a steady supply of packets with fewer refills required.

To support part separation without revealing proprietary details, we used a controlled air assist to help position and space the packets as they exited the system.

Key Components & Features

Vibratory Feeder Bowl

.png?width=250&height=210&name=Bowl%20%26%20Conveyer%20Above%20(Best).png)

Tuned for the packet’s shape and weight to control orientation and flow.

Exit Conveyor

Guides packets into a single file line with consistent spacing.

Elevated Conveyor Hopper

Provides 4.5 cu. ft. of storage to reduce refill frequency.

Custom Spacing Method

Non-contact part spacing method that prevents stacking and overlap.

The Results

We delivered a feeding system that met the customer’s production goals:

Single-File Output – No overlap, no contact between parts

Consistent Throughput – 80 PPM maintained without jams

Less Operator Input – Elevated hopper reduces refill cycles