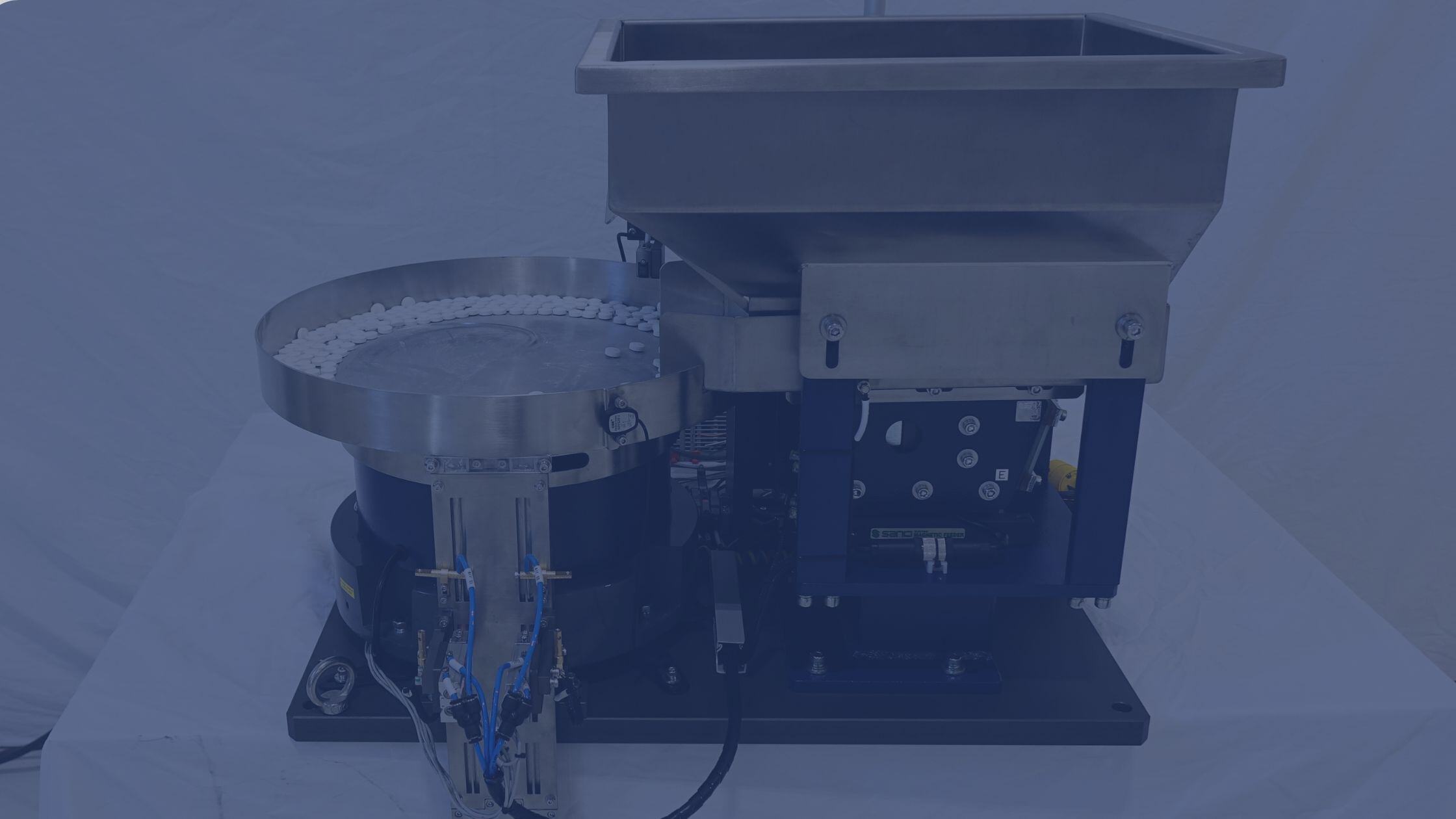

Vibratory Bowl Feeding Feeding and Counting System

Bellco designed and delivered a vibratory bowl system that feeds and counts screws/fasteners with a dual-finger escapement

| Industry | Consumer Goods / General Assembly |

| Parts | Fasteners |

| Rate | Operator Paced; 1 screw released at a time until 4 are released |

| System | Vibratory bowl + tooled track + dual-finger escapement + sound enclosure (polycarbonate on T-slot frame) |

Project Overview

A company in the consumer goods industry needed a system that would count and feed 4 fasteners, ready to be picked up by an operator. The rate of the system needed to be operator-led, in order to prevent back-up.

The Challenge

Many automated parts feeding systems present parts for the next stage in an automated system or for robotic-pickup. In this instance, a human operator is picking the parts four at a time, so we needed to ensure the next four parts are not released until the previous batch is picked.

The Bellco Solution

The Bellco team designed and delivered a vibratory feeding system consisting of a vibratory bowl feeder; a tooled, stainless steel track with adjustable guides, and a dual-finger escapement. The system releases one (1) screw at a time until there are four (4) in a shallow scoop tray, ready to be picked up. The system will not release more until the current batch has been picked. Because this system is operator-assisted, it also includes a polycarbonate sound enclosure to reduce noise and contain debris, creating a safer workspace. The system also includes a sensor across the pick window to ensure more parts are not released until all four are removed.

This system could be built with optional add-ons including:

- An audio/visual light stack for “ready to pick” and “refill needed” states

- Level and jam detection with auto stop

- Part-specific inserts and tooling for custom scoop sizes

How It Works

- Bowl orients and meters parts into the track.

- Escapement releases one screw at a time, counting each release until it reaches four.

-

After counting to four, the system waits for the operator to pick, verified by sensors, before continuing.

- Downstream devices can receive a “4-count complete” signal.

Let's work together on your next parts feeding challenge.

Typical lead time is 12–14 weeks from order to shipment.

Yes, this system could be modified with part-specific inserts or tooling for custom scoop sizes (2Up to 6 Up).

Since this system is operator-assisted and will require an operator to be in close proximity the entire time it is running, a sound enclosure is recommended. This reduces noise and creates a safer work environment for operators.