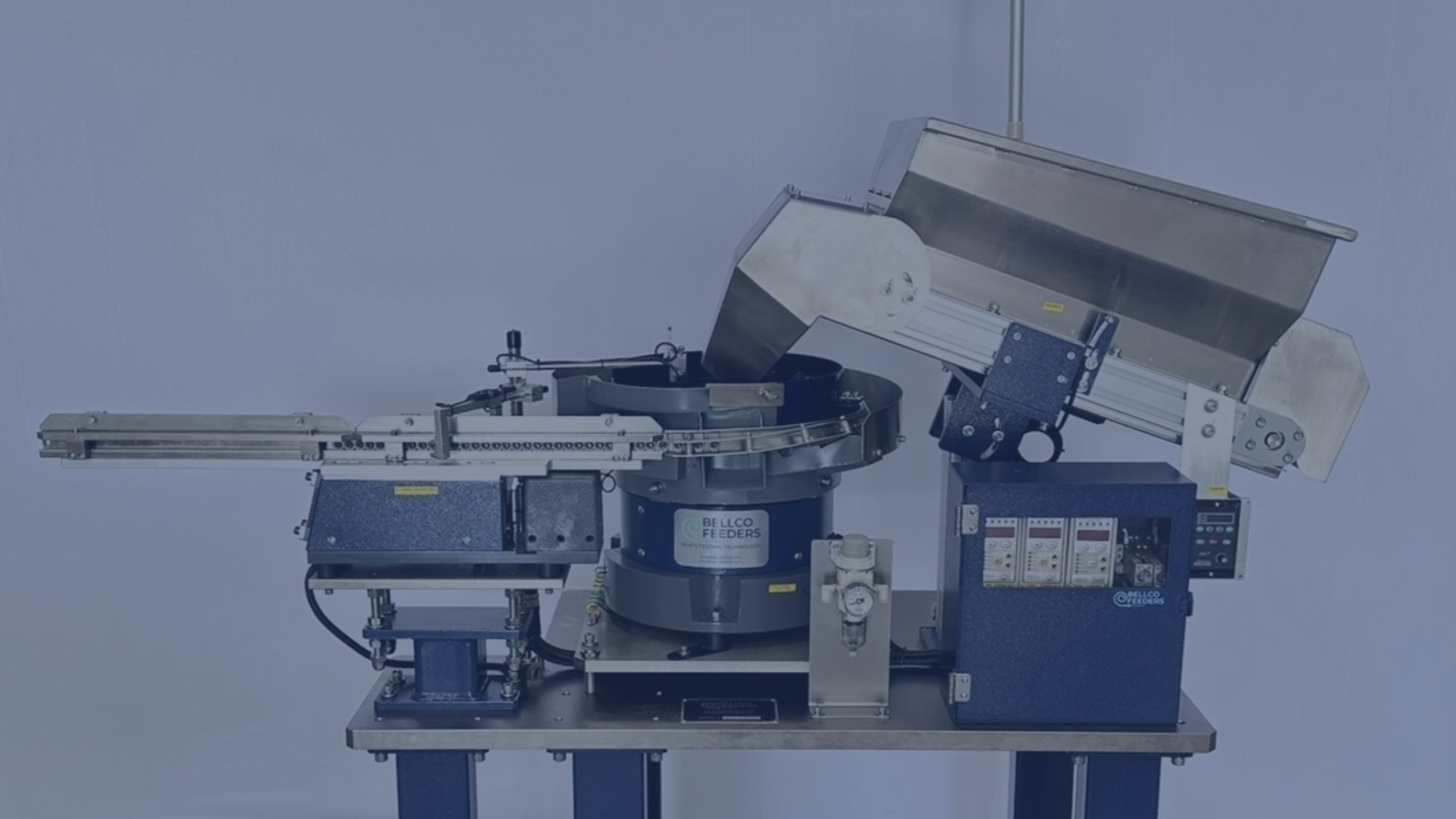

Case Study: High-Precision Vibratory Feeding System for Large Metal Clips

Custom-tooled for large metal clips, designed to deliver perfect spacing for robotic assembly cells.

| Industry |

Solar (also ideal for automotive, aerospace, medical, and machinery assembly applications) |

| Rate | 20 PPM |

| Components | Vibratory bowl feeder, conveyor hopper, dual shuttle escapement |

Project Overview

A major manufacturer in the solar industry needed a reliable parts feeding solution for large metal clips. The challenge: present each part at exact spacing for robotic pick-up, sustain production with minimal operator involvement, and ensure seamless integration into their existing automation cell.

Bellco delivered a high-quality, custom system featuring:

-

A conveyor-fed vibratory hopper providing up to one hour of continuous operation.

-

A custom-tooled 1100mm stainless steel vibratory bowl for precise, repeatable orientation.

-

A dual-position escapement to space parts exactly 200mm apart for clean robotic pick-up every 6 seconds.

-

Integrated smart sensors and EtherCat-ready control system for plug-and-play operation.

Engineering the Solution

We used SolidWorks 3D CAD software to develop a fully customized vibratory feeder system. This allowed the client to visualize the exact configuration before build, ensuring alignment with their production goals.

Key Design Features

-

High-End Dual Escapement: Delivers perfectly spaced parts for robotic pick-up, improving cycle time and accuracy.

-

Conveyor Hopper (4.5 cubic feet): Provides 1 hour of unassisted runtime, reducing downtime and operator involvement.

-

Custom 1100mm Stainless Steel Bowl: Tooled for consistent, directional feed at 20 PPM.

-

Precision Sensors & Controls: Keyence sensors detect part presence; CUH digital controllers provide programmable, responsive performance.

-

Durable Construction: Nickel-plated baseplate, adjustable steel legs, and robust frame for 24/7 factory operation.

Conclusion & Results

The delivered system exceeded performance expectations:

✅ Consistent Output: 20 PPM with accurate 200mm part spacing.

✅ Hands-Free Operation: 1-hour continuous feed time before refilling.

✅ Seamless Integration: Pre-wired and tested with I/O block for easy drop-in installation.

✅ Enhanced Reliability: Built for demanding, continuous industrial environments.

✅ Design Transparency: Client-approved SolidWorks 3D model before build.

This project highlights Bellco’s ability to design, build, wire, control, and debug complex feeding systems for high-precision automation.

Need a parts feeding system?