Case Study: Multi-Lane Vibratory Feeder System for Medical Parts

| Industry | Medical |

| Rate | 240 PPM (20 PPM per lane, 12 lanes total) |

| Components |

|

Project Overview

A medical manufacturing company approached Bellco with a unique challenge: they needed 12 small plastic medical hubs presented simultaneously every 3 seconds, with strict precision and zero margin for error.

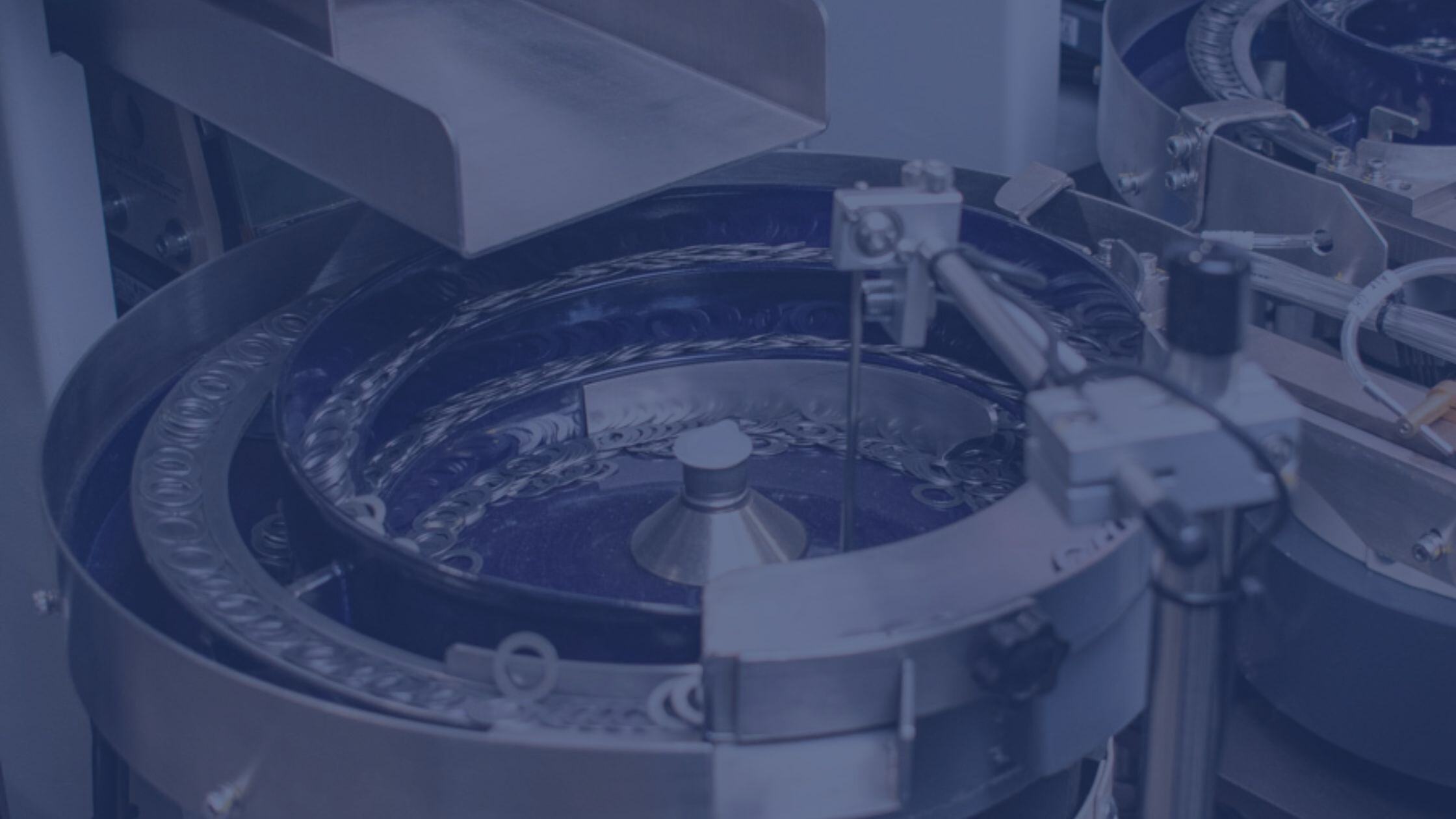

The system had to deliver exact part counts, maintain even distribution across 12 lanes, and integrate into their existing machine. To meet this demand, our team designed a fully custom vibratory bowl feeder system consisting of:

- 2 feeder bowls with 6 individual lanes per bowl

- A vibratory hopper with 1-hour run time to minimize operator intervention

- Smart distribution system to ensure consistent part presentation

With this setup, 12 parts are reliably presented every cycle, accurately meeting the customer’s speed and timing requirements. Our engineering team developed the system in SolidWorks 3D CAD, providing the customer with full design visibility before fabrication began.

.png?width=1200&length=1200&name=Edited%20Picture%20%20(1).png)

The Challenge

Multi-lane feeders can be difficult to manage, particularly when one bowl feeds several lanes at once. This set-up often leads to uneven part distribution, causing delays or inconsistent performance. This customer needed 12 parts presented at the same time, so each lane needed to fill evenly.

The Bellco Solution

Our team custom engineered a smart distribution system that actively monitors part accumulation across lanes. When one lane is full, the system pauses filling that lane and redirects flow to the others. This maintains a steady supply of parts across all 12 lanes and ensures that each cycle hits the precise 3-second target.

Key Components & Features

| Dual Feeder Bowl Configuration | Two bowls per system, each driving six lanes for a total of 12 feeding lanes per cycle. |

|

| High-Capacity Vibratory Hopper | Designed for 1-hour run time to maintain continuous operation with minimal refills. |

|

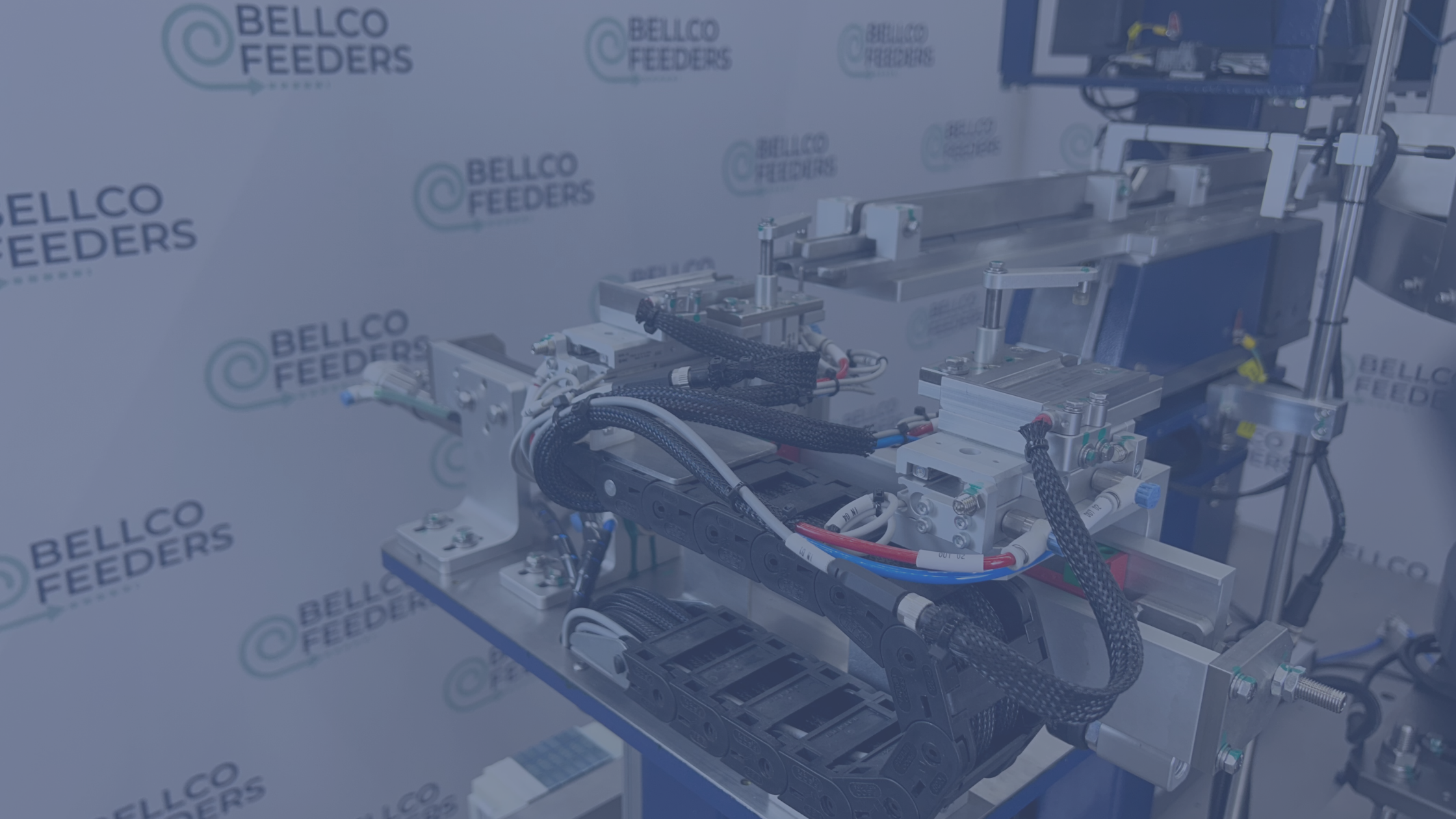

| Lane Auto-Fill System | Custom controls detect when lanes are full and temporarily stop feeding to those lanes, allowing other lanes to continue filling. |

|

| Adjustable Mounts | Customer-specified design allowed them to set screws for final positioning within their existing automation layout. | .jpeg?width=2048&height=1536&name=Customer%20Adjsutment%20Request%20(1).jpeg)

|

The Results

We successfully delivered two custom-engineered vibratory feeder systems that exceeded the client’s expectations for precision, speed, and reliability in a regulated medical environment.

- Synchronized Delivery – 12 medical hubs presented every 3 seconds, with balanced lane distribution

- Reduced Intervention – 1-hour hopper run time minimizes manual oversight

- Smart Controls – Lane auto-fill design ensures even throughput and stable performance

- Tailored Integration – Final adjustment features allowed seamless fit into the customer's existing system

Looking for a custom parts feeding system for your application?